Tech

Tech

IMAGES BY The Author

IMAGES BY The Authort’s been many months since we checked on the progress of the Souza F-100 being built at Gary’s Rods & Restorations. We think you’ll love seeing the work done on the bed, which is largely handmade, with a design that follows the contours of the cab. The outer portion of the rear fenders will stand proud of the contoured bedsides, so it will have a unique character—bringing traditional Ford styling into the modern era. Emilio Belmonte is the primary fabricator on this project, and as you’ll see, the work is done to a very high level.

A reproduction bed and rear fenders were sourced from LMC but they will be highly modified. The original bed was spaced about 1-1/2 inches away from the cab in the center, and with the curvature of the cab that left a sizable gap on each side. Extensions were made for the front of the bed so it closely follows the cab contours, and a piece of 1-1/4-inch round tubing was bent to cap the double walls at the front edge. The wide rear tires required inner wheelwells that were carefully shaped from new metal.

The original bed mounts were very basic, so new ones were made to follow the elegant character of this truck. The mounts started as lengths of rectangular tubing, which were scalloped away and beautifully finished, producing an elegant design.

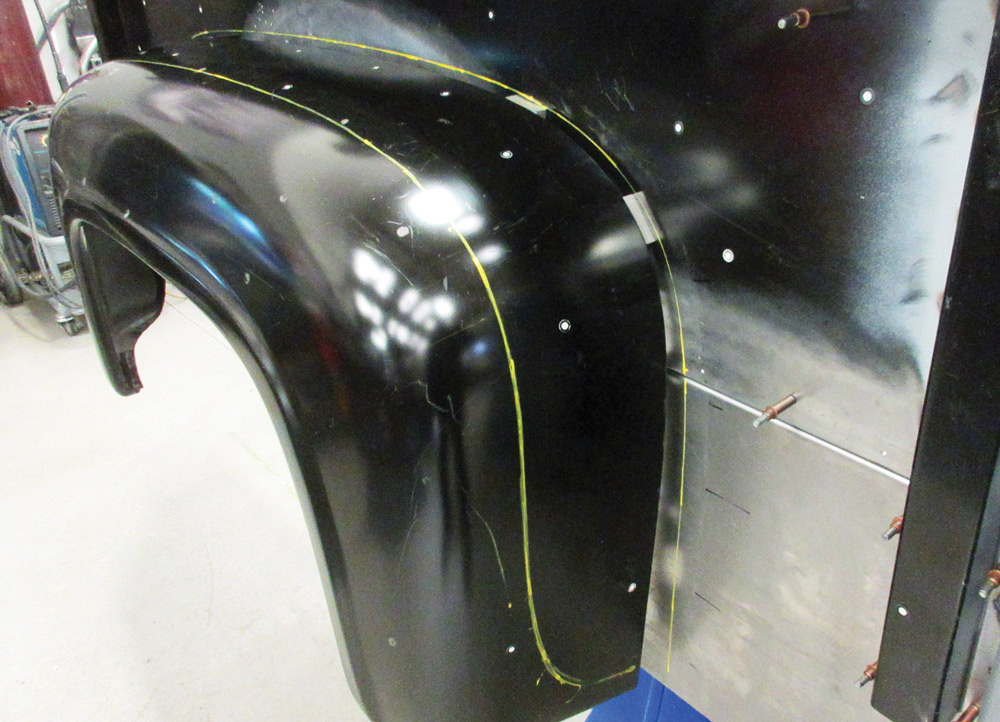

The rear fenders were moved out from the bed to provide adequate clearance for the rear wheels and tires, requiring new mounting flanges to be fabricated. The original flanges pointed inward, but the new flanges go outward to provide more wheel clearance.

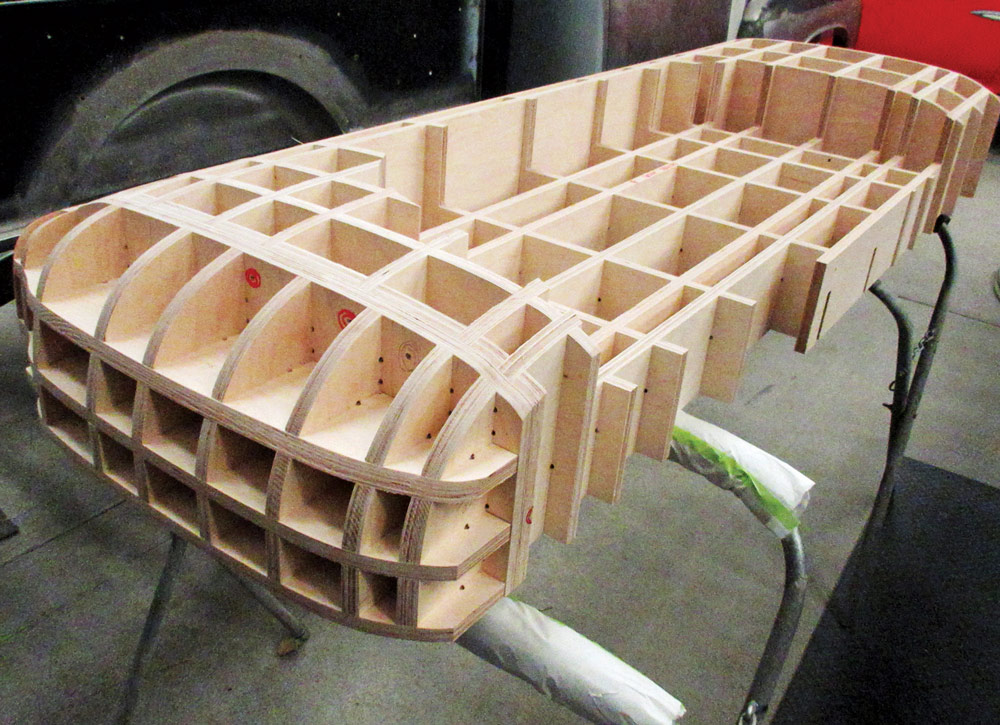

With the bed and fenders mounted, the mock-up of the new bedsides could begin. Everything was scanned first, providing a baseline for the design, then blocks of foam insulation were hand-shaped by eye and masking tape was used to fill in some of the highly curved open areas. The idea was to follow the contour of the cab sides but inset the bedsides a couple of inches. Once the basic shapes were worked out, Sean Sinnott from Designer Grains was called in to model the entire bed in CAD and do the refinement of the shape on his computer.

Once the design was finalized and approved by the owner, Sinnott CNC routed sheets of 3/4-inch plywood to make accurate bucks for the bedsides. We’ll see the shaping of the outer bed in a future article, but the photos here show a wealth of detail you’re sure to enjoy.

SOURCES

SOURCES