Tech

Tech

Photography BY THE AUTHOR

Photography BY THE AUTHORhen it comes to OE instrument clusters, most of our classic trucks leave something to be desired in regards to reliability and accuracy, not to mention aesthetics. Back when these trucks were original, that may well have been good and fine, but with the addition of modern powerplants and the expectation of more accurate information, that old cluster just isn’t going to cut it. Accuracy by way of digital and solid state technology combined with a design that complements any classic truck has become the theme for Dakota Digital’s RTX line of instrument clusters, and their latest offering for ’67-72 Ford F-Series pickups continues that trend.

Dakota Digital’s new RTX Series Retrotech Analog/Digital Instrument Cluster is not only a great visual improvement to the interior of any ’67-72 Ford F-Series truck, but a practical upgrade as well. Utilizing microprocessor technology, the RTX dashboard monitors solid state sensors, transmitting the digital data directly to precision stepper motor-driven gauges. This digital capability combined with solid state reliability results in unparalleled accuracy when it comes to keeping a keen eye on your truck’s entire powertrain system. Full LED backlighting provides over 30 user-selectable color options that allow independent treatment of the needle, sweep, and digital TFT display color. Daytime and nighttime settings ensure that the instrument information is displayed in a manner that is easily consumed, regardless of the lighting conditions.

A septet of analog gauges includes a 0- to 120-mph speedometer, 0- to 80-psi oil pressure, 100- to 250-degree water temp, fuel level, and 9-17 VDC voltmeter. Tachometer display is above the analog speedo in the form of a 0- to 8,000-rpm digital bar graph gauge. Built-in warning indicators for the fuel, volt, water, oil, and tach gauges help give the driver a heads-up before things turn for the worse, complemented by turn signal and high-beam indicators.

Digital, full-color TFT displays are user-configurable to display a myriad of additional information, including various performance readings as well as additional analog gauge information in digital form. Additional expansion modules allow for even more information to be displayed, including GPS speed, compass heading, outdoor temperature, wideband air/fuel, and more. Interface modules for most aftermarket EFI systems are also available, providing further information from intake air temp to fuel pressure to MAP readings. Additionally, the RTX Series Instrument System can be combined with an OBD-II Interface Module to receive various engine parameters directly from many modern OE ECUs, making installation a truly plug-and-play affair.

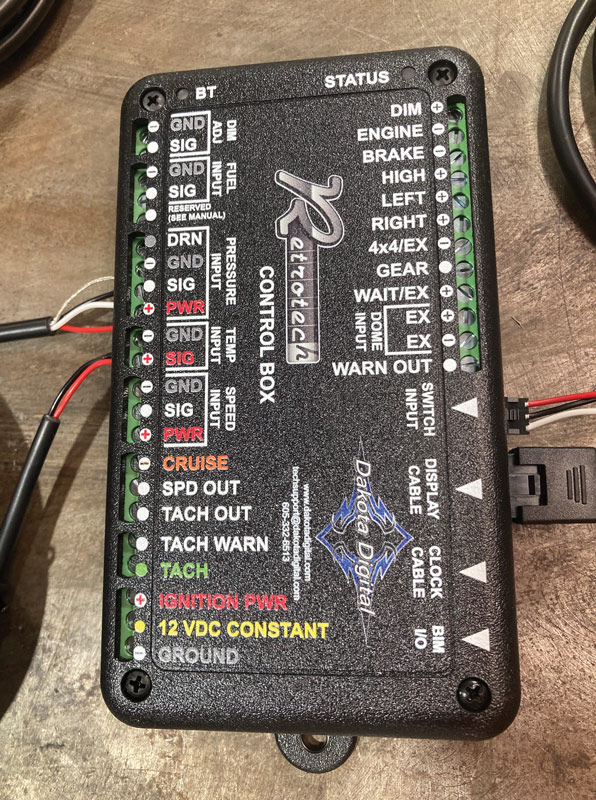

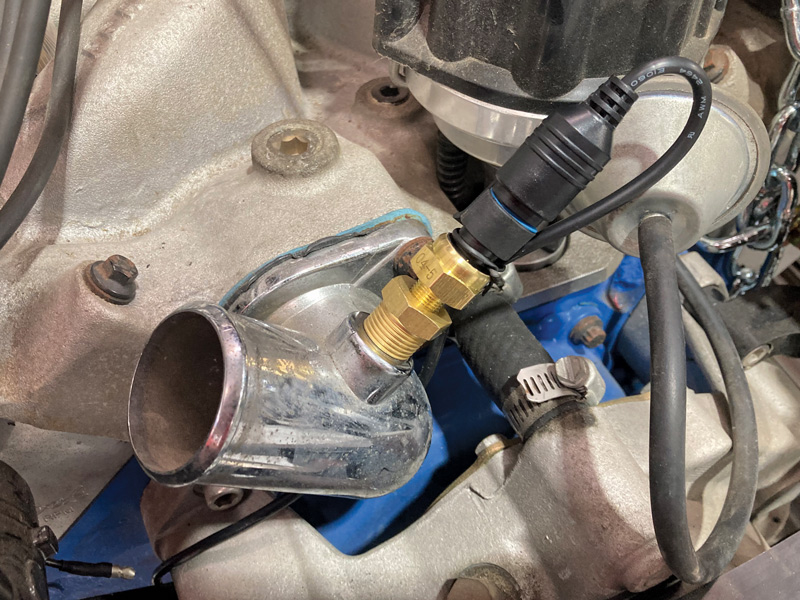

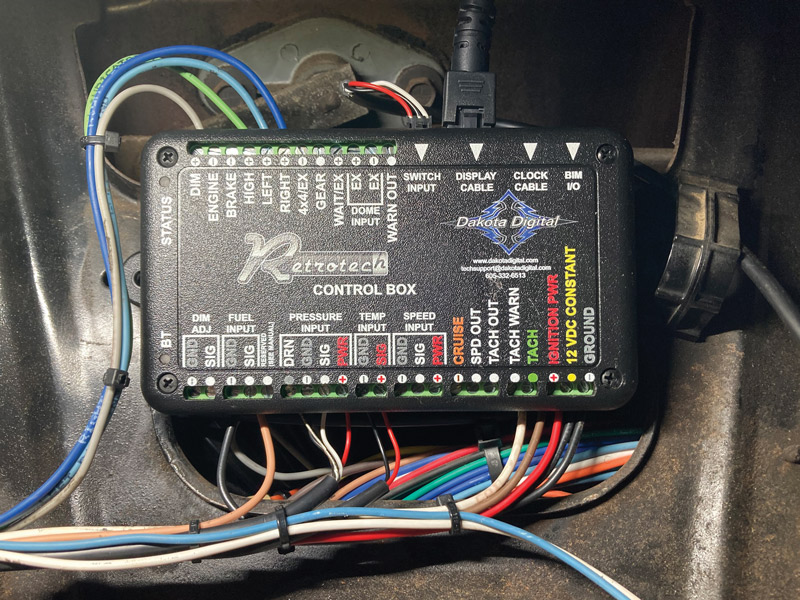

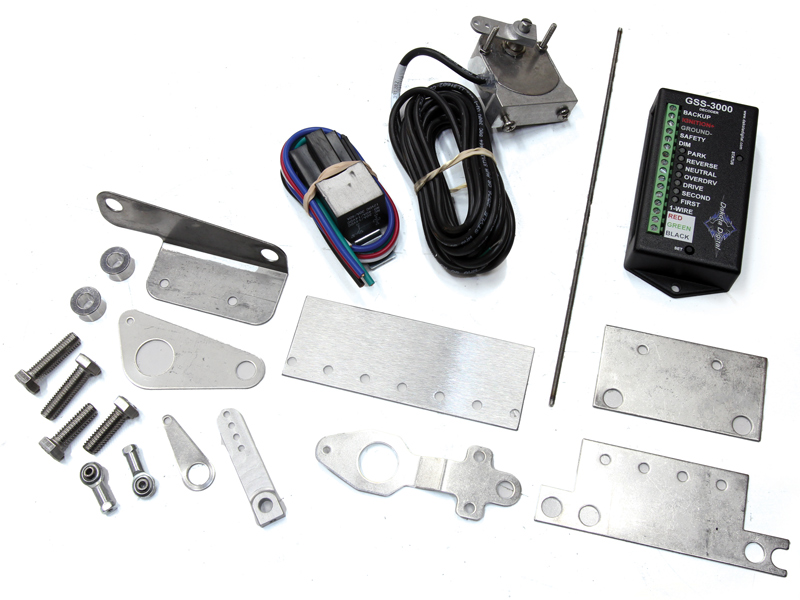

As advanced as the Dakota Digital line is, the installation is not. Solid state sending units provide the appropriate information to the control box via individually wired pigtails, making connection of the various sensors as simple as possible. Ignition and battery power, as well as chassis ground wires are run separately to the control box from the fuse panel or corresponding source. Likewise, turn signal, high beam, and other inputs are also routed individually to the central control box. That information is then shared to the instrument cluster via an eight-pin cable.

We’ve been working on a ’69 Ford Flareside project recently and when it came time to upgrade the old, tired cluster, we knew there was no better option than Dakota Digital’s RTX system. Designed to attach directly to the original gauge bezel as a complete instrument cluster replacement unit, it was one of the biggest drop-in upgrades we’ve made so far. We’re pretty excited to get it set up as our truck build progresses and can’t wait to see how well it monitors our stroker FE motor!

5-6. Here, the water temp and oil pressure sensor cables are attached to their respective locations on the control box. The selection switch attaches in a similar fashion and is used to toggle between the various menus used for programming and setup of the system. An 8-pin cable connects and communicates between the control box and the instrument cluster.

SOURCES

SOURCES