Feature

Feature

PHOTOGRAPHY BY THE AUTHOR

PHOTOGRAPHY BY THE AUTHORot Rodder Mike Little is no greenhorn when it comes to the vintage truck scene. His last creation, a Pro Touring–styled ’52 Chevy pickup, made the rounds on social media and even landed a cover feature in a classic truck magazine. So, when Mike sold off that pickup to free up some cash and much-needed space in the family garage, it was only natural that another needy truck would soon find its way to the Littles’ homestead, situated in bucolic Spring Grove, Pennsylvania.

They purchased a ’65 C10 shortbed showing only 66,000 miles on the odometer. It was also sporting its original six-cylinder and three-speed setup. It did have some modern modifications added to it, including an air suspension setup, disc brakes, and drop spindles, but it still maintained an overall old-school look. The truck was skinned in an older repaint, which was luckily still in good shape, displaying some nice patina on its outer panels.

The game plan was simple: Fix the minor rust issues in the lower body while keeping the skin mostly intact. Next, add an upgraded suspension underneath it for driveability and then infuse the classic truck with a healthy dose of horsepower underhood. Though the truck would receive a little outside attention from local shops, the majority of the work on this particular C10 would be done in the Littles’ home garage.

The C10 had been sold to Mike straight out of Pattinato Hot Rods just outside of Pittsburgh, Pennsylvania. The shop installed the air suspension setup and upgrades on the pickup as well as performed some cleanup of the chassis and body before passing it onto the Littles. Mike wanted to keep some of the modifications made over the years by its past owners while adding his own “grocery list” of goodies to this new build.

The suspension received plenty of love here. Mike intended on keeping the air ride basics while upgrading where he could. First off, Firestone 2600 airbags were sourced and added up front to the chassis to help get this “bedded” hot rod to rise and fall at a drop of a switch. McGaughy’s supplied 2 1/2-inch drop spindles along with a set of their gas-filled shocks (built on custom mounts) to help out with the ride up front. Out back was a similar scenario, but Mike chose Firestone 2500 airbags mounted on BC Fabrication brackets to levitate the back side of the truck. A Performance Online adjustable trailing arm crossmember was then installed after it was modified for additional driveshaft clearance. The stock trailing arms were reused, after being installed with fresh urethane bushings and a set of 2-inch lowering blocks.

Out back Mike decided he wanted something unique for his factory shortbed C10. After some thought he roughed out a concept, drew custom patterns, and fabbed up a one-off aluminum bed floor, complete with rear wheeltubs and raised tunnel for the rear axle housing out back. From there it was bead rolled by local guru Shannon Shimmel and brush finished by wife Lisa to obtain the look they were after. The finished product is a sight to behold.

Once the body and chassis were near complete, the owner moved to the four corners of this pickup. For stopping power Mike went with a GM 12-inch disc brake setup. Out back, the 11-inch drum brakes were rebuilt to help handle this C10’s power curve. A Wilwood power brake assembly with an adjustable proportioning valve makes sure that all four corners get plenty of push. When it comes to what this Chevy rolls on, the owner put a lot of effort into making this modernized classic still look the part of a vintage hot rod truck. So for that old-school appeal, a foursome of GM transport 22-inch rims were grabbed up for the project. To keep that theme moving along, a set of original ’64-66 C10 dog dish caps were installed. For rubber, the owner skinned his rims with Falken Ziex S/TZ05 tires in 265/35-22, both fore and aft.

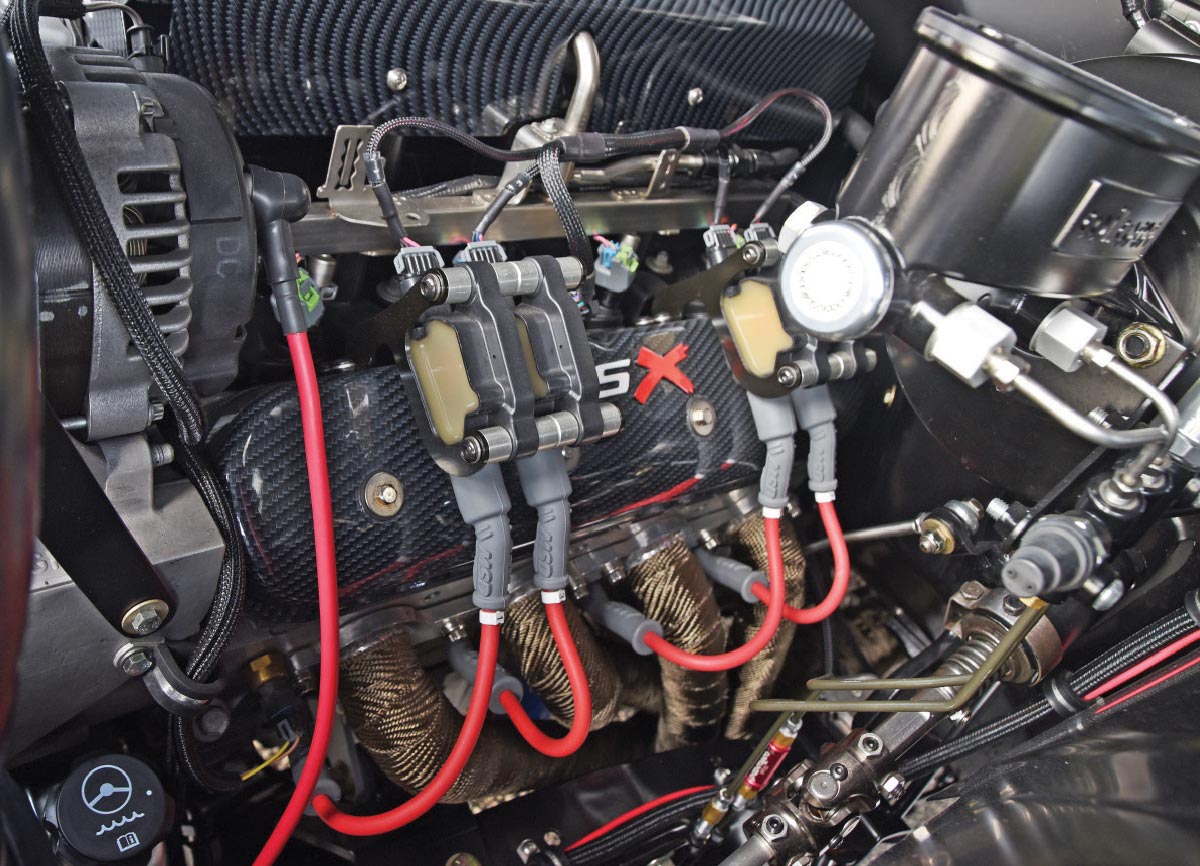

Other highlights to this C10 include a Boyd’s 19-gallon aluminum fuel tank with an Aeromotive Stealth 340 electric fuel pump to dole out the go juice to this thirsty LS. A ViAir 380 compressor and 3-gallon tank mounted underbed helps this C10 rise and fall on Mike’s notice. In the engine bay, a set of modified LSX valve covers give a clean look to the LS2. The owner fabricated a cover to hide the TBSS intake as well. Hydro graphics were done by Dave Whisler at Pigeon Hill Designs right there in Spring Grove. The final tuning on the LS2 was done by Calvin Nelson out of York, Pennsylvania, using HP Tuner software. With 435 hp at the rear wheels, it has certainly got the power to scoot on down the highway.

As far as the build goes, there were ups and downs. “The first windshield didn’t fit right. Changing suppliers fixed that. Since we did basically zero bodywork, a lot of time was spent adjusting and shimming to get good gaps … and of course those typical startup and running issue gremlins,” Mike states.

As far as the future, the couple have plenty of plans that involve this stealthy C10. But there are some things that probably won’t happen in the next few years. “Our buzzword with this truck that was shared with many people was ‘restraint.’ Keep the patina, fabricate less, no body mods. The running joke with our friends and family was when are you gonna break down and paint it? Our inner circle thought we’d crack and get out the paint guns. We didn’t!”

As with any build, sometimes you need a little help from friends. Mike says, “I want to give a big thank you to my friend Chris Moscarell who trailered the C10 home from Pittsburgh. He also supplied plenty of specialty tools during the build and was my sounding board during the process. A shout-out also goes to Shannon Shimmel for the custom sheetmetal work, TIG welding, and machinework.”