Tech

TechInTheGarageMedia.com

IMAGES BY THE AUTHOR

IMAGES BY THE AUTHORwould safely say that 7 out of 10 people were dumfounded when I told them of my intentions to convert my ’69 Chevy from a factory (SWB) Fleetside to a Stepside—that ratio only increased (or decreased, depending on how you look at it) when people saw that I was not only serious but actually went ahead and did the conversion! OK … it’s my truck (and Old Anvil Speed Shop now has a decent/complete Fleetside box in which to use for their ’67-72 All Access bed floor kits!) and I’m standing behind my so-called aesthetic blasphemy!

All kidding aside, I used to be a devout Fleetside fan—but have always had an attraction to Squarebody ’73-80 Chevy/GMC Stepsides, though I never made the backward transition with my ’75 Cheyenne before (regretfully) selling it. With the ’67-72s, however, it wasn’t until quite recently—more specifically, when featuring James King’s Delmo-built ’71 on the cover of our June ’22 issue—that I became more fascinated with the early Steps. (To be fair, Classic Truck Co.’s Spot Thomas’ ’67 Stepside has also been a major inspiration!)

You may be wondering why I would do such a thing. Well, for a couple reasons. The obvious one being the personal preference aspect, but also because (assumedly) the truck’s already painted. Well, the first reason is null and void as far as I was concerned, but to address the paint, let’s just say the camera does wonders—and on top of that, due to the Slosh Tubz being very poorly molded to butchered-up front fenders, I’ll also be swapping out the front sheetmetal! So …

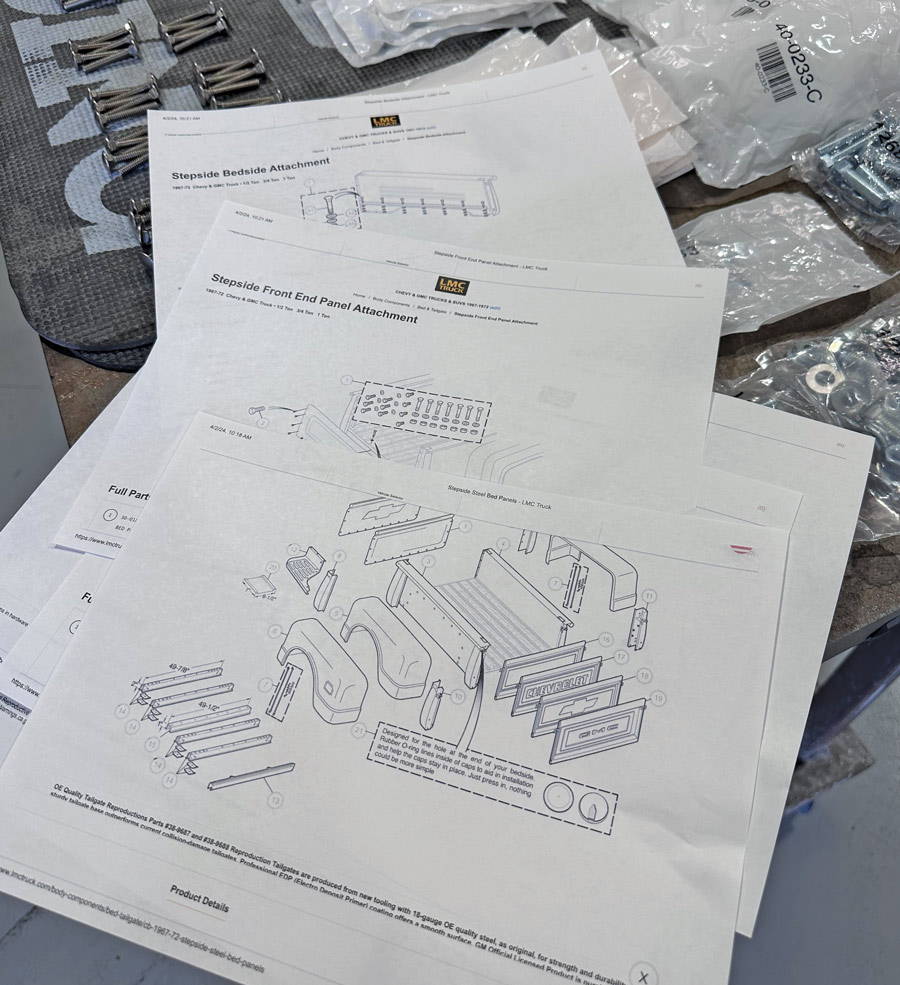

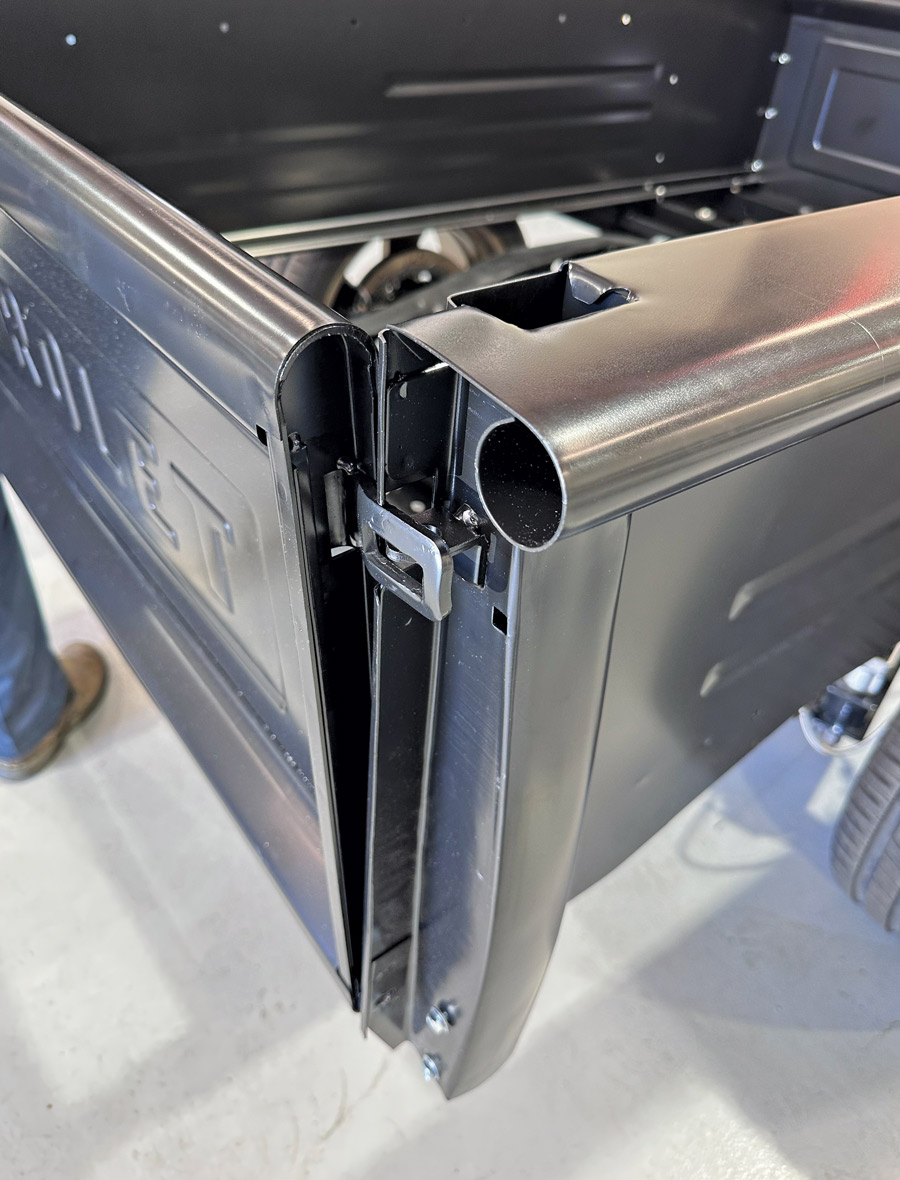

We started off by hauling the ’69 down to Old Anvil one Wednesday morning where they quickly removed the existing Fleetside bed and all its associated components. After I’d spent some time on the web/socials looking at “pre-owned” Stepside bed options (missed a cherry complete bed with fenders and all in Cherry Valley for $500 by a few hours!), I decided to look at my aftermarket options. When all was said and done, an order was submitted with LMC Truck that very day, and the following week Ryan Manson and I were ready to start the assembly/installation process! (I will note that, in order to properly align and fit and fully mount a Stepside box, you will need the accompanying bed floor as well. Since I will be ordering a new wood base from BedWood in the near future, Manson simply made spacers the thickness of the planks to accommodate for the time being.)

Once the truck comes back from getting some new threads at TMI then finally—FINALLY—up and running at FiTech, she’ll come back to our tech center for the new BedWood floor and retro front sheetmetal install!

SOURCE

SOURCE