Feature

Feature Photography By tHE AUTHOR

Photography By tHE AUTHOR

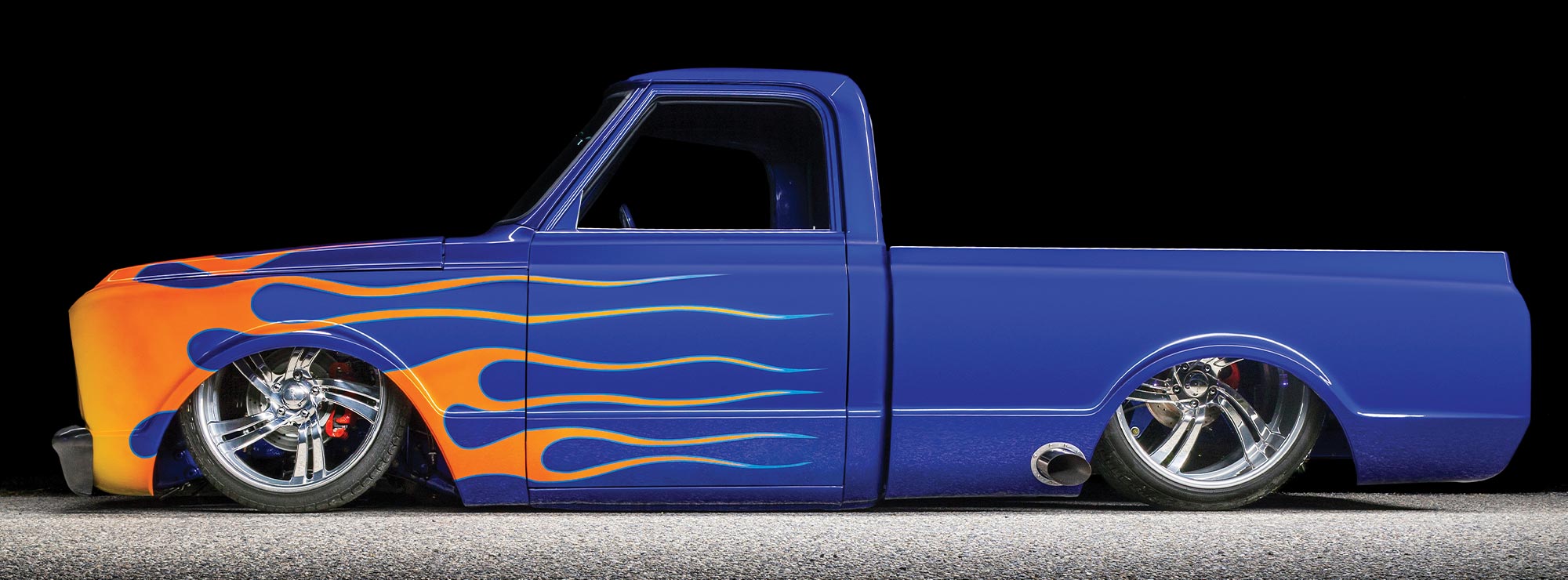

he automotive fascination that takes place for many at an early age is usually easier to explain when you’ve been born into it. Parents are the first shapers and in Mike Slayton’s case his immersion into the automotive world came about as a direct influence from his father, Dale. As the owner of a performance-oriented shop, he was instrumental in setting his son on a path that would not only encompass his spare time, but also help shape a career path. Mike recalls, “I started hanging out at the shop when I was 10.” Dale was hard-core when it came to the mechanical side of the business and was very savvy at squeezing horsepower from an engine. He was also an avid racer by flogging cars down the quarter-mile on Friday nights and Sprint Car on Saturdays. The other thing that he saw early on in his son was his ability to draw, so as a Christmas present he was given an airbrush. By the time he was 13 Mike was doing airbrush work on Harley-Davidson gas tanks and murals on car hoods, and at the shop Dale had him doing small things like running boards or truck caps to get a feel for laying down car paint. By the time he was 16 he had honed his skill set to the point of doing full paint on cars.

Vehicles were always coming and going at the shop and one day a totaled ’87 Nissan pickup came in that caught his eye, to the point that he bought it. “I was into mini-trucks when I was a kid because that’s all I could afford. I couldn’t afford street rods,” he points out. That purchase set him on a path to redo that truck and he eventually built it up with a complete drivetrain from a twin-turbo Nissan 300ZX donor. That was a two-year project that culminated with features in Mini Truckin’ and Tailgate magazines.

That truck was in his possession for about eight years until it was sold off in 2010 to buy a ’55 Ford pickup. A ’72 Chevelle also joined the fold and both stayed with him until 2015 when they were sold off. At that point he was doing a lot of side work for other people and putting in long hours at his day job as a body and paint technician with the Maryland Transit Administration working on damaged buses. Those long hours that turned into long weeks— and months—eventually caught up with him. That fueled the desire to find a new project. By 2019 he was ready to pull the trigger on another vehicle but didn’t have a clear idea on what he wanted, which led him to search for the low-hanging fruit online. Surfing on craigslist brought him to this ’68 Chevy C10.

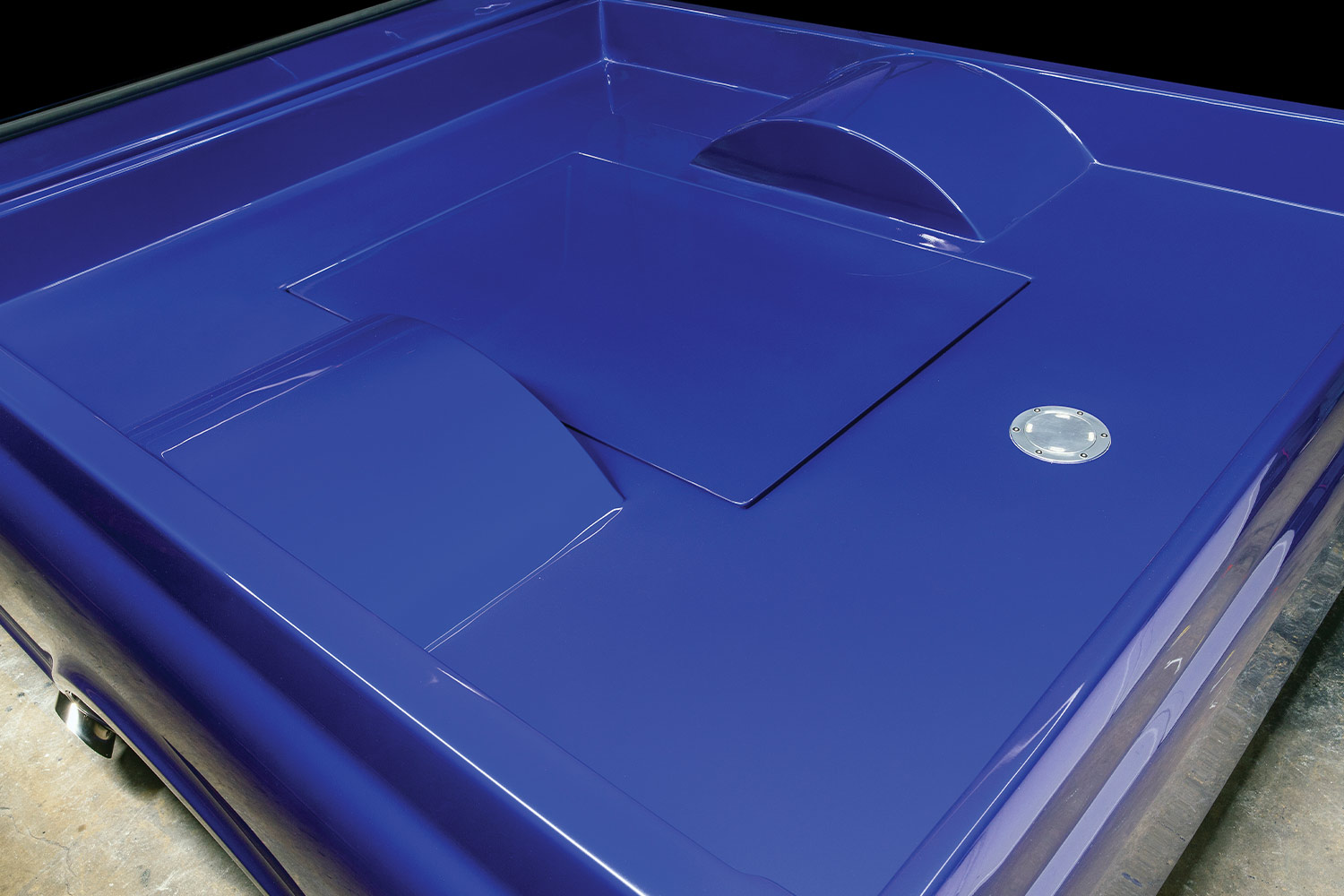

Right as that order was placed for the chassis the COVID-19 lockdowns started to increase and the difficulty in getting parts became a real thing. With no clear delivery date set, he moved onto replacing all the rusty sheetmetal and modifying the bed. He raised it 14 inches and fabricated new tubs and an access door along with a smooth tailgate and roll pan. Other modifications included the relocation of the turn signals from the front grille to the shaved front bumper and the addition of a third brake light. Just as all the bodywork was wrapping up the frame was delivered. It was at that point that the wheel and tire combo also landed. The choice that Mike made was based on a fair amount of time looking online and measuring in the garage. He opted for a set of Raceline Charger billet wheels (22×9 front, 24×15 rear) that he wrapped with Pirelli P Zero tires (245/35ZR22 front, 405/25ZR24 rear).

The remainder of the drivetrain was also sorted while the frame was away. Mike’s comfort zone was body and paint, so when it came to dealing with the mechanical side he went looking for reputable places. For the engine he contacted Skip White Performance in Kingsport, Tennessee, for one of their 383 stroker stage 2.0 crate motors. The foundation for that package is based on a cast-iron Dart block with a Scat forged crank, Scat connecting rods, Comp Cams roller cam, and Wiseco 10.5:1 forged pistons on the bottom end. On top it wears AFR Enforcer aluminum heads, Edelbrock Performer EPS 2701 intake manifold, MSD Street Fire HEI distributor, and a Holley 750-cfm carburetor. Backing that up is a TREMEC TKO 500 sourced from Silver Sport Transmissions. It is equipped with their SST Advanced Friction clutch, and a RAM True Balance billet flywheel. Running toward the back is a two-piece custom driveshaft from A-1 Drive Shaft Company in Baltimore, Maryland, which is mated to the original GM 12-bolt rear that Mike had narrowed 14 inches and then fitted with 3.73:1 gears and shortened Strange axles. The exhaust system consists of Hedman ceramic-coated headers mated to 3-inch stainless exhaust pipes with cutouts and Borla ProXS mufflers.

Once the chassis was dropped off from the powdercoaters it was set up in the garage. First on the install list was a 4-gallon tank for the air suspension along with Ridetech fast valves and two ViAir 444C chrome air compressors. After those were installed, the rest of the suspension and wheels were mounted. With the remainder of the components on hand, Mike spent 17 months assembling the truck. The last hurdle he faced as everything came together was installing a new interior. From TMI Products he sourced a set of bucket seats and door panels. Tucked between those seats is a custom-made center console to house a 12-inch Kicker subwoofer and Auto Meter Pro-Comp Ultra Lite gauges, which were also included as part of the dash cluster. Also added was an ididit tilt column, Lokar billet shifter, Forever Sharp billet steering wheel, and a Kenwood 10.1-inch head unit with a full complement of Kicker speakers.

This was a three-year journey for Mike of late evenings and long weekends spent in the garage. The payoff has all been very positive. He states, “So far its first year out has been really great and it has done really well at every show we have taken it to. One of my other goals was to see if I still had what it took to build something that was magazine worthy. I feel great that goal has been accomplished.” He does acknowledge that none of this would have been possible without the help—and patience—of his wife, Kelly, who has been a supportive accomplice all along.