Tech

Tech

by Ron Ceridono

by Ron Ceridonof all the OEM components embraced by performance enthusiasts, Ford’s 9-inch rear axle assembly has to be at the top of the list. Over the years they’ve become almost standard equipment under modified vehicles regardless of the make, and for good reason. They’re tough, a wide variety of gear ratios are available, and changing centersections, or the pumpkin as it’s often called, is easy.

The 9-inch was produced from 1957-86. To put things in perspective, when the last of these rearends came from the factory under a new Ford, Ronald Reagan was in the White House, the average price of a gallon of gas was $0.90, and Seinfeld was the number one TV show. Given the fact that the 9-inch has been out of production for awhile it would seem that complete assemblies and individual parts would be hard to come by, but that’s not so. Strange Engineering is well aware of the advantages to the 9-inch Ford rearend and can provide everything new, from individual parts to complete assemblies.

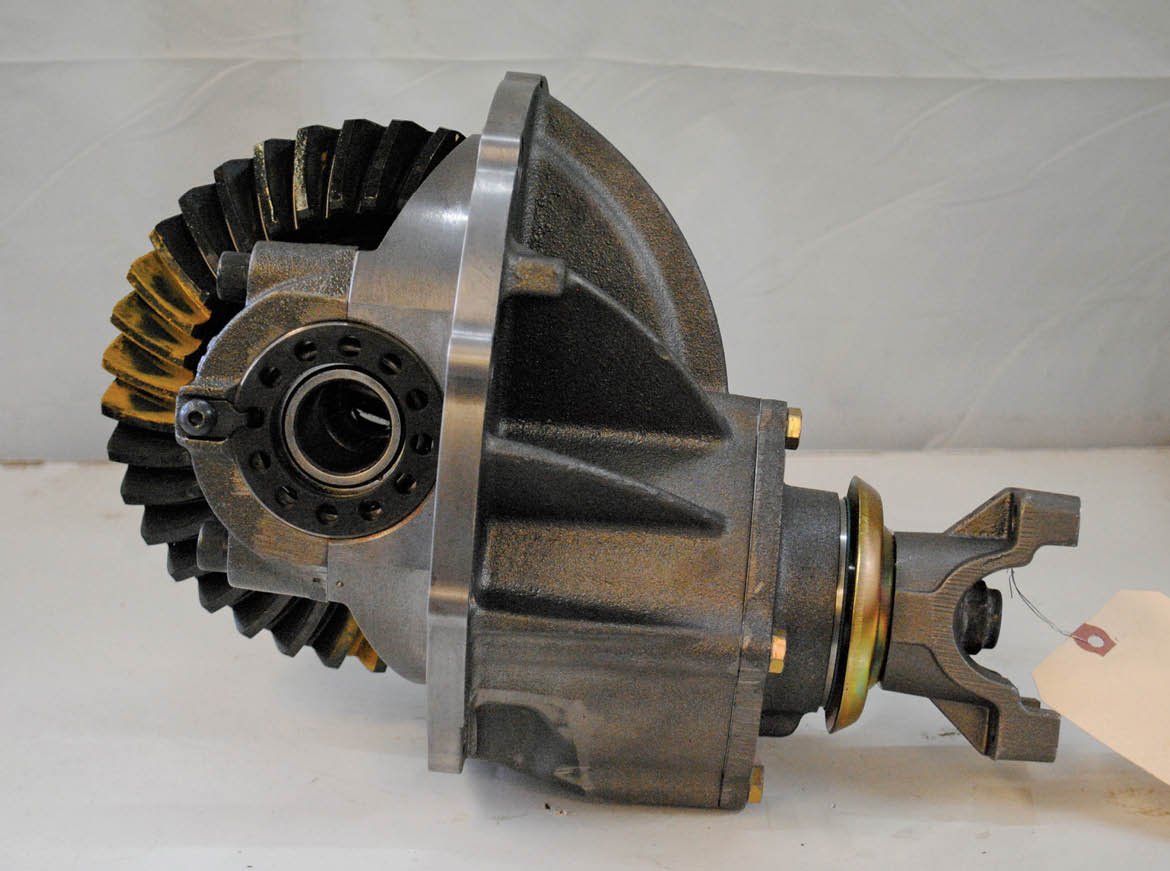

The design of the Ford 9-inch is Hotchkiss style, which is to say the case containing the third member, or the ring-and-pinion assembly, is removable as a unit. By comparison the Salisbury design, like the later Ford 8.8 and others, have the third member components mounted in the axle housing, which makes gear installation and adjustment much more complicated.

A notable feature of the Ford 9-inch is both a big advantage as well as a slight disadvantage. To improve the tooth contact and strength, as a result, the pinion is low on the ring gear when compared to other designs. As explained by Strange, “This larger offset (hypoid distance) between ring gear and pinion gear centerlines is the key reason the Ford is inherently stronger but also why it’s slightly less efficient.” Arguably one of the reasons for the demise of the 9-inch was the effort to increase fuel economy with a more efficient, albeit somewhat weaker, rearend.

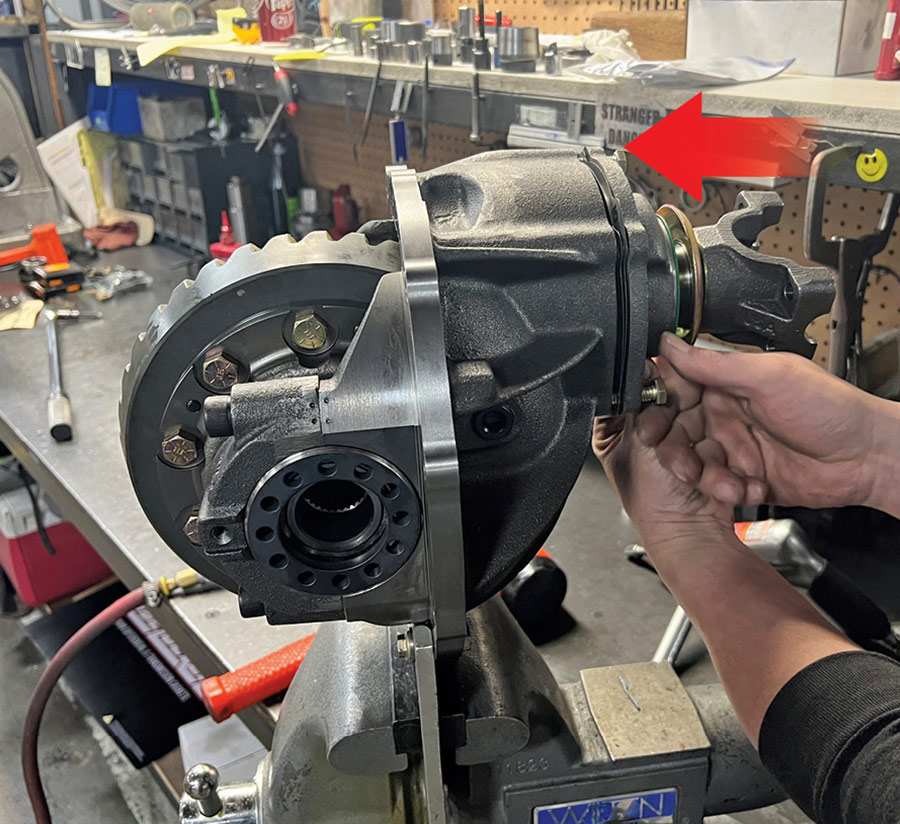

Another reason for the popularity of the 9-inch is the method of retaining the axles. These rearends use pressed-on bearings and lock rings on the axles, which are held in the housing with retainers bolted to the flanges on the axle tubes. If an axle should break the wheel will stay attached to the housing. By comparison the Ford 8.8 and GM 10-/12-bolt axles are held in the housing by C-clips inside the differential case. That means a broken axle, along with the wheel and tire, can come completely off the car. (Strange does offer C-clip eliminator kits that resolve that problem, and rear disc brakes act as retainers to some extent).

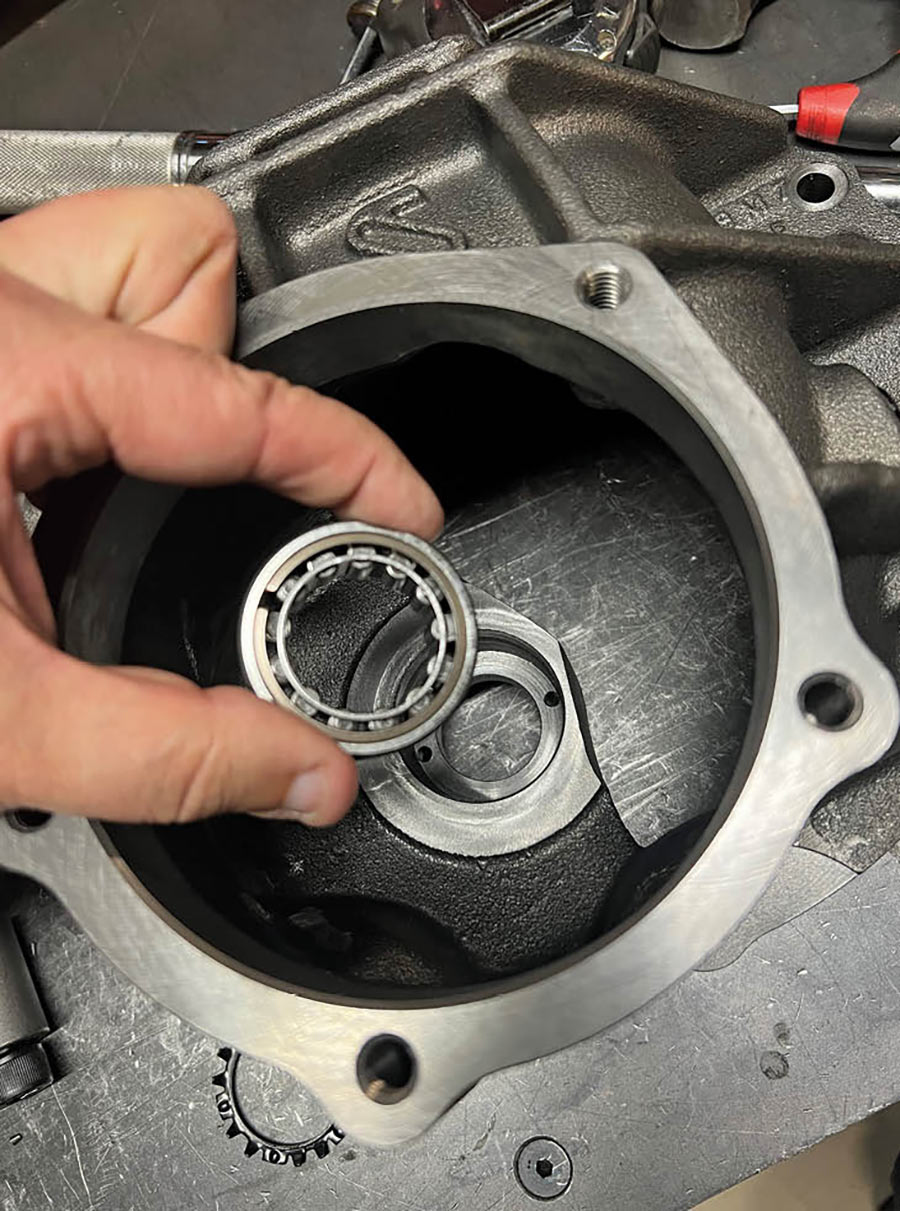

Strange offers a variety of new 9-inch housings. For our application, a ’71 Ford pickup, we chose an HD housing (PN HF9FT65F100ME). The centersections are fabricated from 0.141-inch mild steel with internal gussets for rigidity; the stout axle tubes are mild steel, 3-inch-diameter, 0.250-inch wall thickness. Another consideration when selecting an axle housing is what axle ends are required, which is dictated by the axle bearings that will be used. There are three distinct 9-inch axle ends: the early big bearing, the late big bearing (Torino), and the late ’65-73 small bearing. We opted for the early big Ford ends (PN H1135) with tapered wheel bearings (PN A1013). These bearings offer exceptional life in street applications as they handle side loading much better than ball bearings.

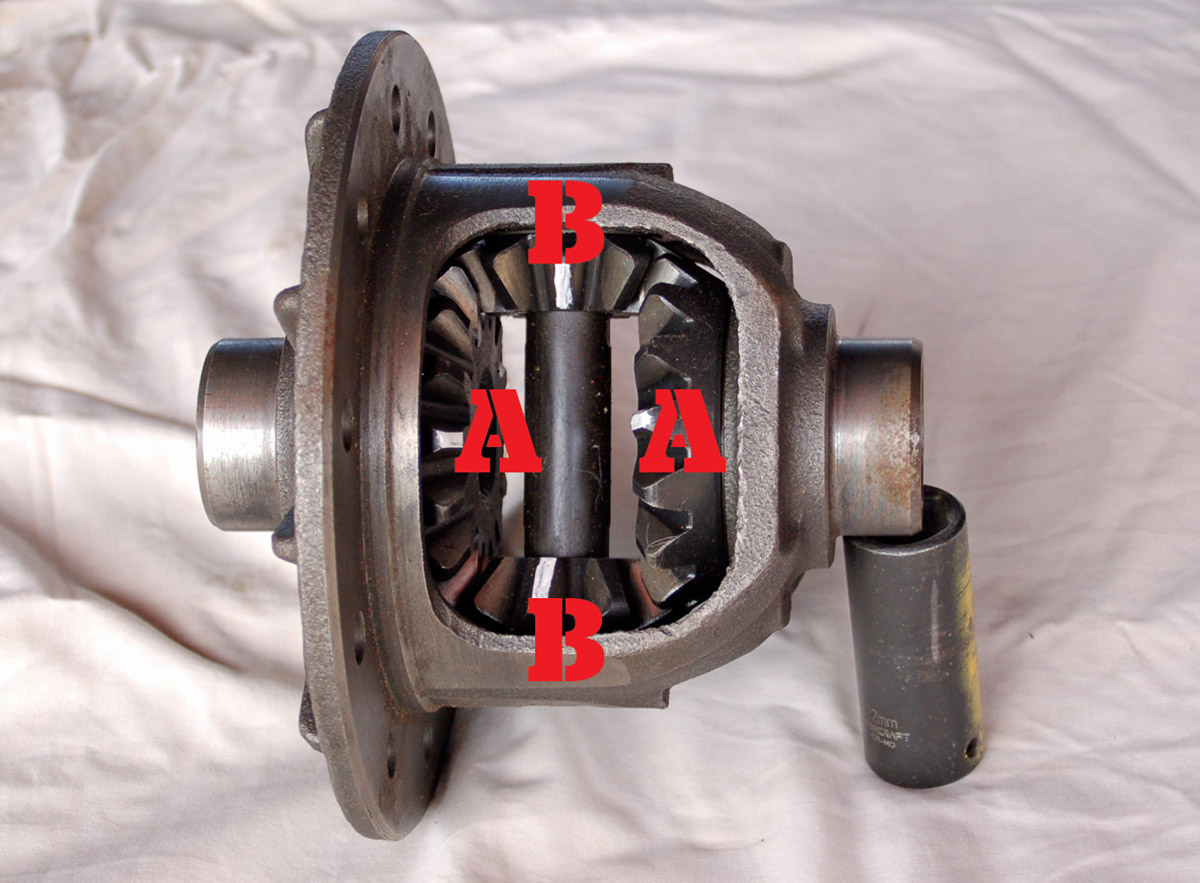

When selecting rearend components, a common question is what type of differential to use. As a car, or in this case a truck, turns a corner, the outside drive wheel travels further than the inside wheel. As a result, the outside wheel has to turn faster—the differential allows this to happen. The most common type of differential is the “open” style. The problem with this design is that when one tire loses traction the differential will transfer all the power to that wheel. The proof of that is the well-known one-tire burnout. To put power to the ground from both tires there are a variety of limited slip units, aka Positraction differentials, available. We picked an Eaton Truetrac (PN N1979) for its smooth, seamless operation and durability. In addition, they don’t require special lubricant-like, clutch-style units and aren’t noisy like a locker.

The heart of the rearend assembly is the centersection. Strange offers a variety of case assemblies in iron and aluminum. For our application we went with an S-series nodular iron case (PN PRF130). Stronger than the factory nodular iron case, it comes with a cast-iron Daytona pinion support (PN N1914) that uses larger bearings compared to the standard factory support and a heavy-duty 1350-series U-joint yoke (PN U2203). This case will accept a wide variety of ring-and-pinion ratios; in our case we chose a 4.11:1 gearset from U.S. Gear (PN RS07890411US).

One of the common questions when it comes to selecting axle is spline count, which is another way to try and quantify strength. Unfortunately due to a variety of factors, including vehicle weight, horsepower, tire size, and so on, coming up with meaningful strength numbers for axles is impossible. So consider this: Base 28-spline axles are reasonably tough, but for performance applications use 31-spline axles because they are 35 percent stronger and are appropriate for most street-driven vehicles. For more serious applications when compared to 28 splines, 33 splines are 60 percent stronger, 35 splines 77 percent stronger, and 40 splines are 198 percent stronger.

The Ford 9-inch rearend assembly was introduced 66 years ago and has been out of production for 37 years. Yet today this mainstay for performance enthusiasts is better than ever thanks to Strange Engineering’s effort to improve them. It just goes to prove some things really do get better with age.

SOURCE

SOURCE