Tech

Tech

IMAGES BY TAYLOR KEMPKES

IMAGES BY TAYLOR KEMPKESn the previous (Mar. ’24) issue of Classic Truck Performance we looked at the growing popularity of ’88-98 Chevy and GMC trucks and SUVs, like the Tahoe, Yukon, and Suburban. As we explained then, this series of vehicles has been labeled as the old body style (OBS) to distinguish them from the styling of those that would follow in 1999 (Tahoe, Yukon, and Suburban styling stayed the same through 2000). While we admit it seems like labeling anything from that era as a “classic” is pushing the envelope, when you consider they are in the 26- to 36-year-old range, it puts things in perspective. Like we said on the subject last month, time really does fly by.

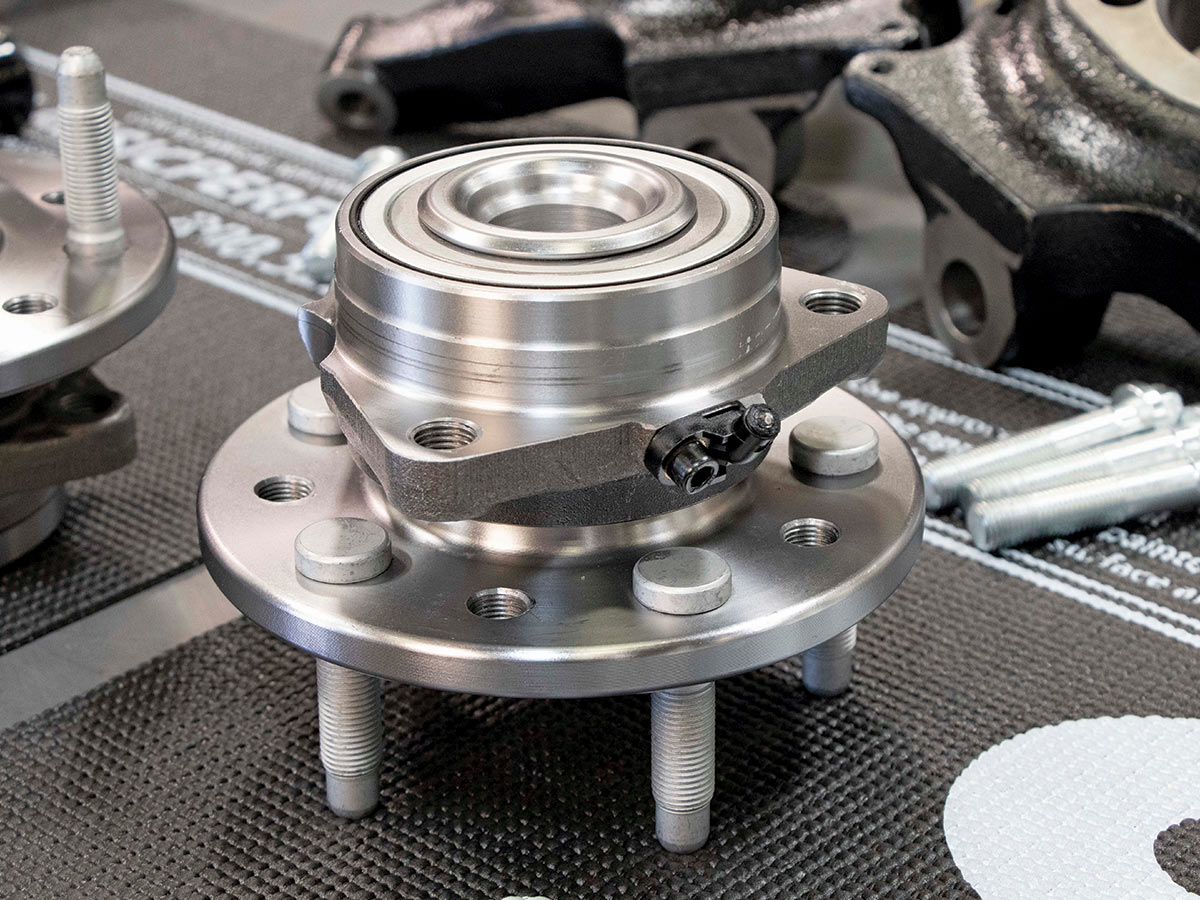

The ’96 Tahoe shown here has already been treated to CPP’s tubular control arm and coilover conversion (PN 8898FCO-K). These components narrow the tread width 1.5 inches per side for increased tire clearance while the coilovers with double-adjustable shocks allow the suspension to be tuned for optimum ride and handling characteristics. This time around we’re installing CPP’s new Big Brake assembly (PN 8898SWBK-X10-5). Included in the kit are CPP’s X10 Extreme Drop Modular Spindles that are similar in design to those found on late-model Corvettes. Cast from high-quality ductile iron, these spindles lower ride height by 2-1/2 inches and are designed to accept the big brake assemblies available from CPP. These spindles use the ultra-strong, bolt-on, Corvette-style sealed bearing and hub assemblies that eliminate the hassle of packing the bearings with grease and adjusting them.

Included in the front brake kit are 13-inch, cross-drilled, gas-slotted, zinc-washed rotors that mount to sealed bearing hub assemblies. Putting the squeeze on the rotors are PBR C15 calipers with twin 52mm pistons that significantly increase the clamping force on the rotors when compared to the stock GM calipers. The calipers attach to the spindles with the included custom brackets.

At this point we should point out that this Tahoe, like many other vehicles of this vintage, is equipped with ABS (anti-lock brake system). Basically, what this system does is monitor the speed of each wheel with a sensor. If the sensor sends a signal indicating a wheel has locked up, the controller “pulses” the hydraulic pressure to that brake, eliminating the skid. The CPP hubs come with an ABS sensor that simply plugs into the existing wiring harness, keeping the factory system operational.

Installing CPP’s Big Brake Kit involves removing the entire stock spindle and brake assembly as none of it will be reused. Installing the new components is simply a matter of bolting them in place as no modifications to the vehicle are necessary. Keep in mind once the installation is completed it will be necessary to bleed the brakes and whenever suspension components are replaced a trip to an alignment shop is required. Then it’s time to drive and enjoy your updated new classic.

SOURCE

SOURCE