Tech

Tech

1. Glenn Sinon is known for his craftsmanship and innovation. Check out the Chevrolet script taken from a rocker cover that has been cleverly integrated into the LS Fabrication firewall installed in his latest project.

Glenn Sinon’s Latest After-School Project

BY RON CERIDONO Photography by CTP STAFF

Photography by CTP STAFF

t seems like Glenn Sinon has held a body hammer or a spray gun in one hand or the other for most of his adult life. He’s worked in body shops, is a former training instructor for PPG, and today Sinon teaches collision repair and refinishing at A.I. Prince Technical High School in Hartford, Connecticut. So what does he do in his spare time? He builds spectacular cars in his home shop—Sinon’s Ford Maverick was featured in our sister publication Modern Rodding, he’s won best paint at the Detroit Autorama, and received the Master Builder award at the Boston World of Wheels.

Sinon’s latest project is a ’51 Chevy five-window pickup and we were lucky enough to catch the early stages of its construction. The frame has been completely boxed from front to back. In addition, the rear of the framerails were trimmed on the outside then boxed to provide clearance for the rear tires.

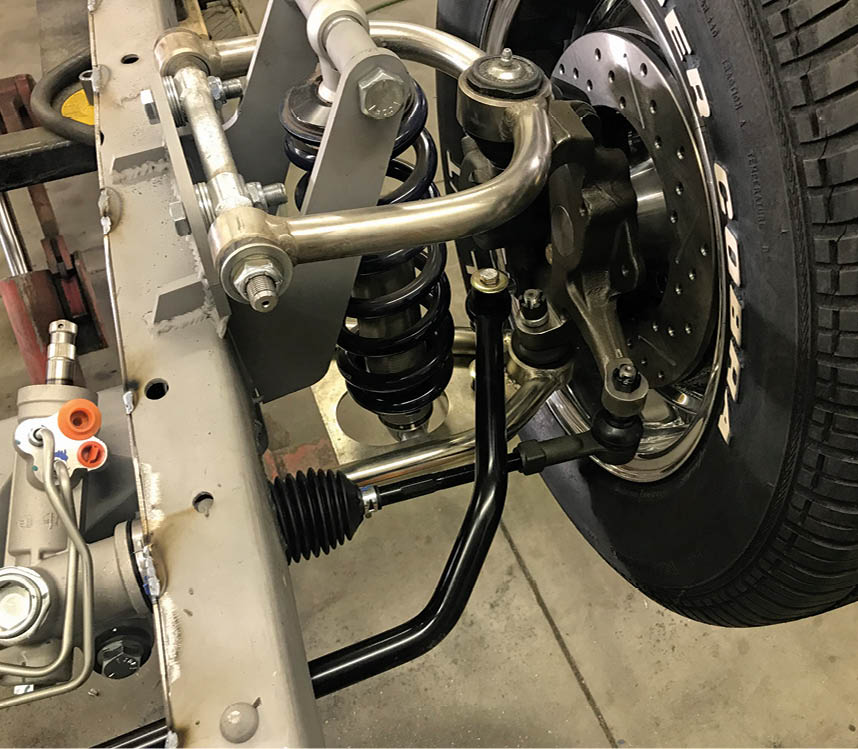

To update the front suspension and steering those components have been swapped for a Fatman Fabrications Mustang II IFS with power rack-and-pinion steering. The stock torque tube–equipped rearend has been replaced by a Ford 9-inch assembly; the brakes are now discs from ECI up front with Ford drums in the rear. Ridetech coilovers are used all around.

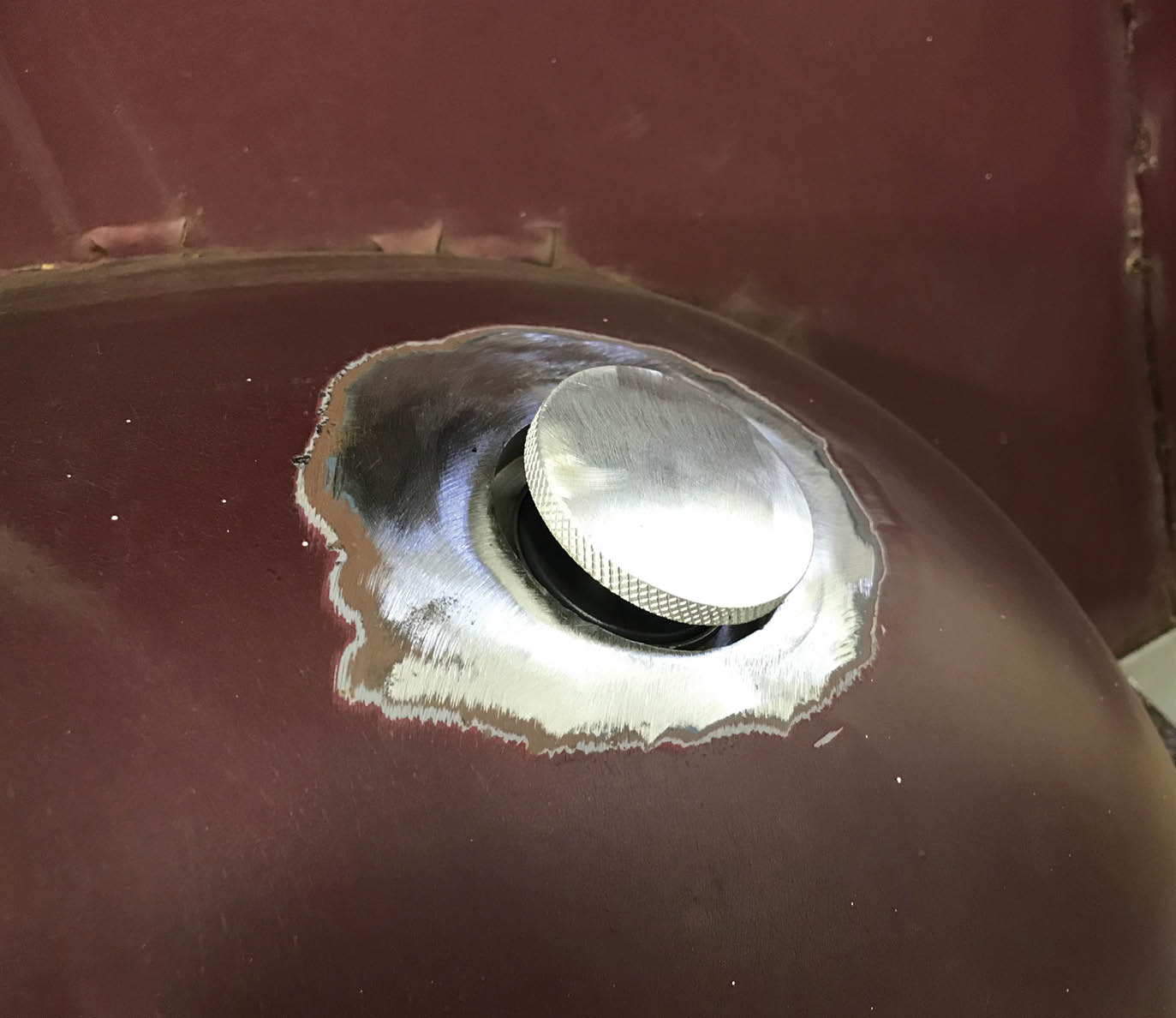

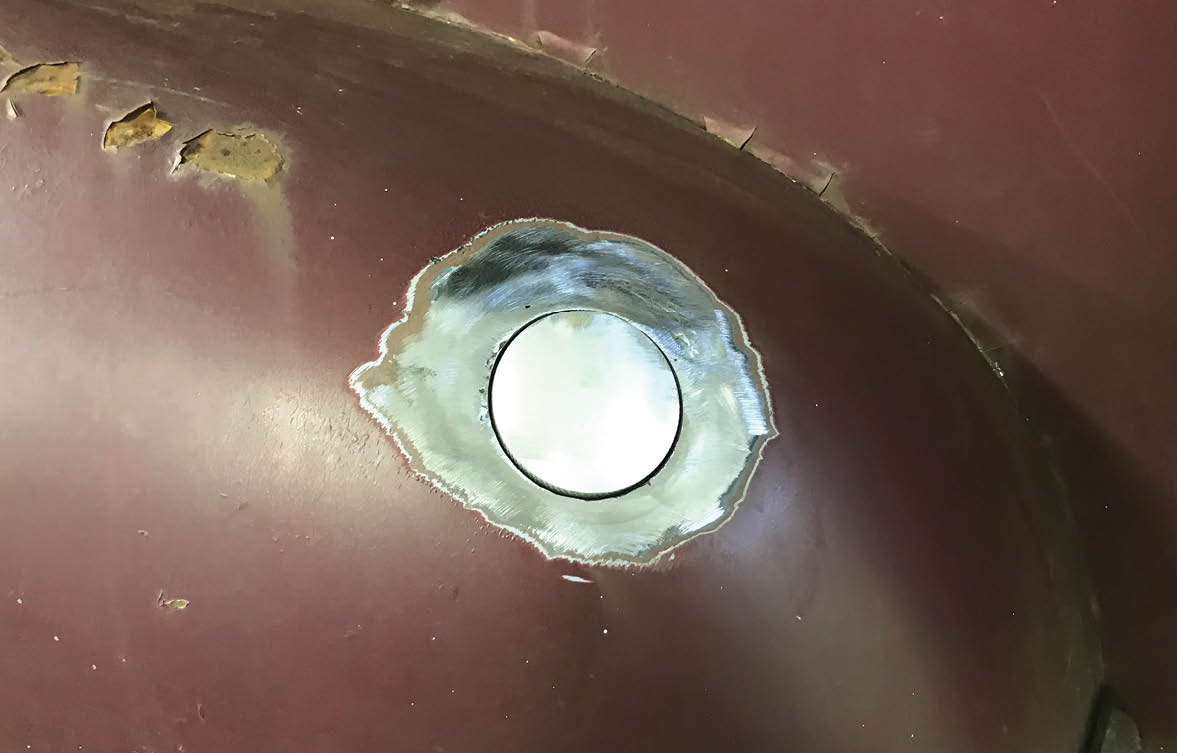

Sinon wanted to eliminate the in-cab gas tank and mount one under the bed. However, he doesn’t like the through-thefloor filler that most use, so Sinon fabricated a filler pipe and located a pop-up gas cap in the left rear fender—it’s unobtrusive and convenient.

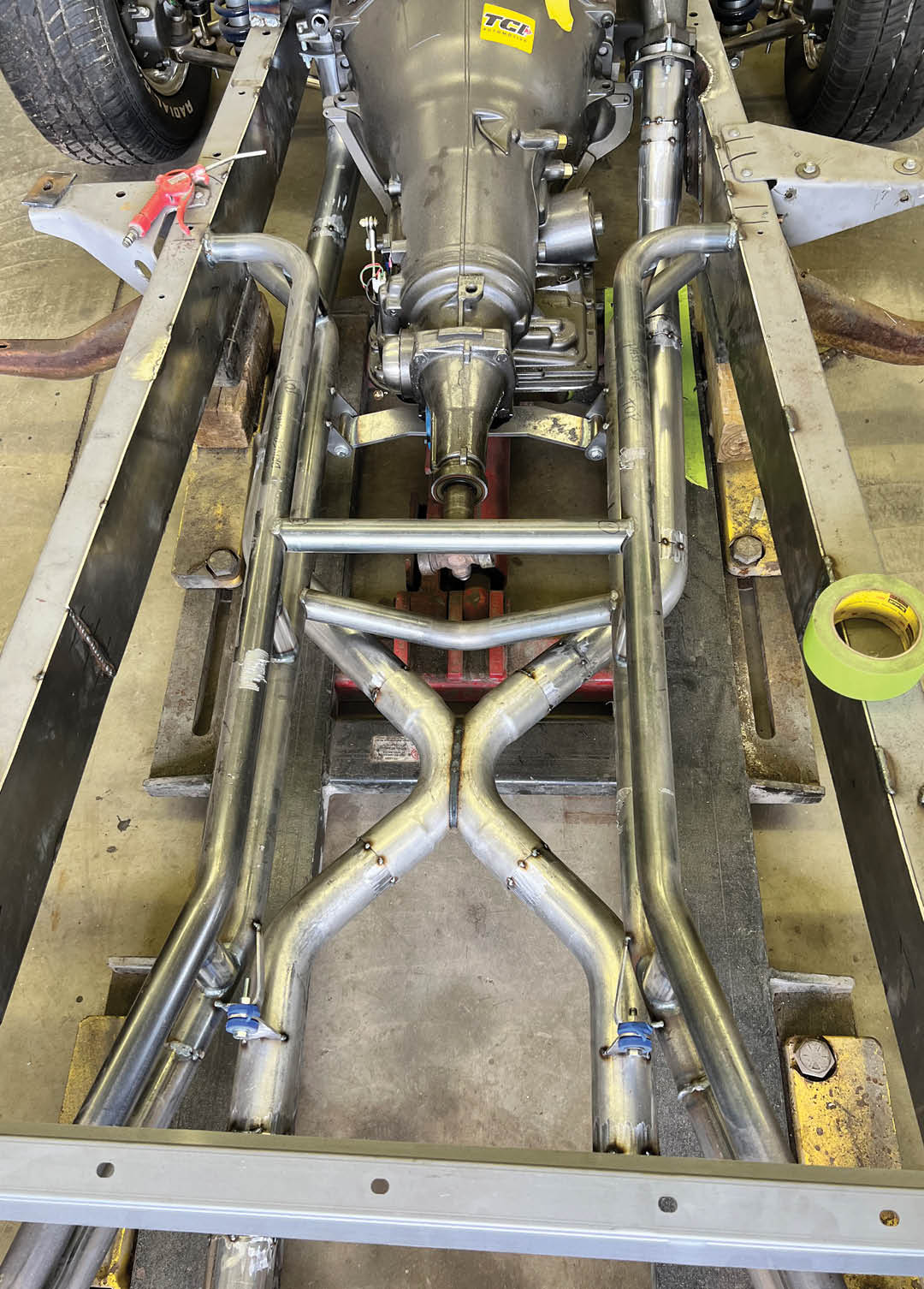

With the chassis modifications complete, the engine and transmission mounts in place, and the exhaust system fabricated, the frame was sent out for powdercoating. Once the frame was back in Sinon’s garage a Chevrolet crate engine was installed. While that doesn’t seem unusual, his choice of this particular crate engine is. Sinon opted for a Chevrolet Performance CT350—this 350ci small-block is designated the “GM 602” and is a sealed circle track crate engine for factory stock class racing.

While the CT350 sounds like an odd choice for a street engine, it’s not as outlandish as it seems. These engines are based on a four-bolt main block, have iron Vortec cylinder heads, and a pump gas–friendly 9.1:1 compression ratio. A unique dual-pattern camshaft helps deliver more than 300 lb-ft of torque between 2,000 and 5,500 rpm peaking at 396 lb-ft at 3,800 rpm, which makes for a super stout street engine with plenty of pulling power that’s reliable and not the least bit temperamental. The “602” came with an 8-quart circle track racing oil pan, harmonic balancer, HEI distributor, and an aluminum high-rise, dualplane intake manifold, which Sinon swapped for a Chevrolet Performance Ram Jet fuel injection system. Backing up the small-block is a 700-R4 from TCI Automotive.

With the chassis a roller, Sinon will now turn his attention to bodywork, paint, and adding the dozens and dozens of the exquisite details he’s known for. We’ll stay in touch and keep you up to date with the progress of the teacher’s pet.

2. The finished chassis for Sinon’s truck rolls on ET III wheels; fronts are 15×7, rears measure 15×10, tires are Cooper Cobra 225/65R15 fore and Hoosier 29×12.50R aft.

3. With the stock steering and suspension removed the frame was then placed on jackstands and leveled. The Fatman Fabrications crossmember was temporarily put in place to check the fit. Note the rails have not yet been boxed.

4. Cardboard templates for boxing plates were made. Note the reference mark on the frame (arrow) indicating the front axle centerline.

5. To make the frame rigid the ’rails were boxed their entire length with 1/8- inch plate.

7. Rather than using Mustang II–type slots for alignment adjustments, this Fatman IFS has vertical plates that the upper control arms attach to. Note how the upper coilover mounts index into the mounting plates for the upper control arms (arrows) for strength and to position them properly.