Tech

Tech

Photography BY the Author, Michael Christensen & Gary George

Photography BY the Author, Michael Christensen & Gary Georgehe crew at Gary’s Rods & Restorations has been working diligently on Jason Souza’s ’56 F-100. The most recent work has been on the front fenders. For reasons that are unclear, these trucks were designed with the wheelwell opening far off the center of the fender, pushed back close to the back edge.

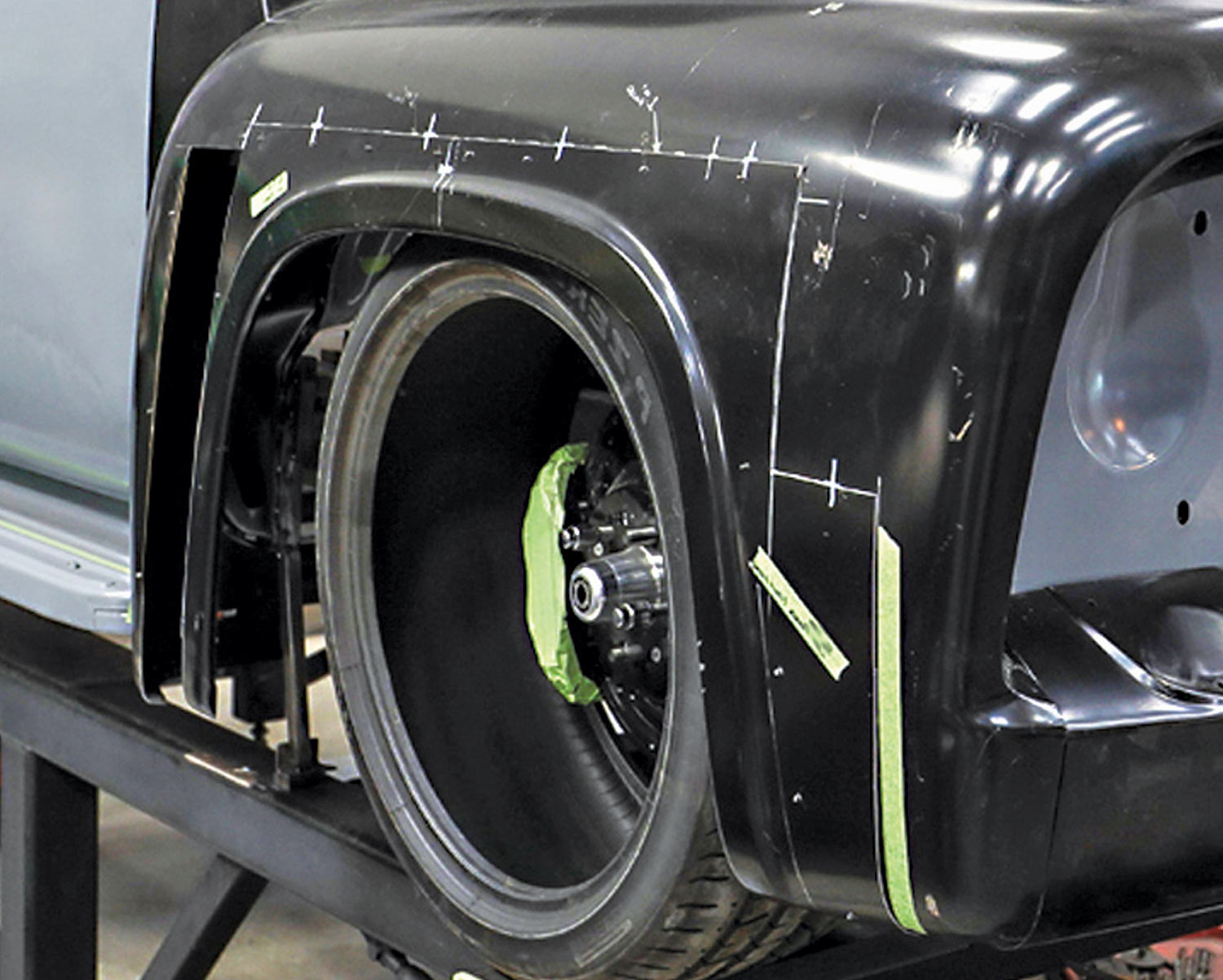

It’s a fair amount of work to move a wheelwell, but Jason thought the work would be justified, and we think you will agree when you see the finished product. Knowing this change was coming, the new front suspension was located on the truck’s frame so the wheels could be centered in the fenders.

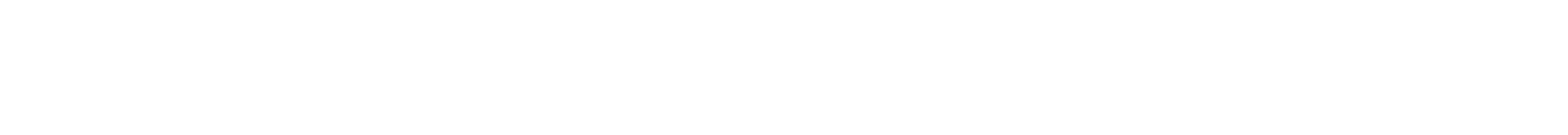

One of the first steps in modifying the fenders was laying out the cuts for the original wheelwell, with the goal of placing the joints in places where the edges would fit together reasonably well in their new location. With the original wheelwell cut out, it was centered on the wheel and checked visually to make sure it looked good from all angles. It was raised about an inch and a couple of “nips and tucks” were required to get the proportions just right.

Once all the fitting and adjusting was completed, a filler piece was welded to the back edge of the wheelwell and metalfinished. Then the assembly was positioned on the fender and the edge of each joint was scribed and trimmed. The joints were then tack welded together, using a butted joint. After working the joints lightly with a hammer and dolly, the joints were TIG welded and metalfinished.

One of the challenges with work like this is getting both sides to match—you just can’t get sufficient accuracy with a tape measure. Emilio Belmonte, Gary’s chief sheetmetal technician, devised an MDF fixture that ensured symmetry with both wheelwells and then precisely located them at the correct height on both sides of the truck. It’s little details like this that really help to maintain a high level of consistency with work of this nature.

The photos show each step in detail. Look forward to many more articles on this exciting project.

SOURCE

SOURCE