Tech

Tech Photography BY CTP STAFF

Photography BY CTP STAFFInstallation 101

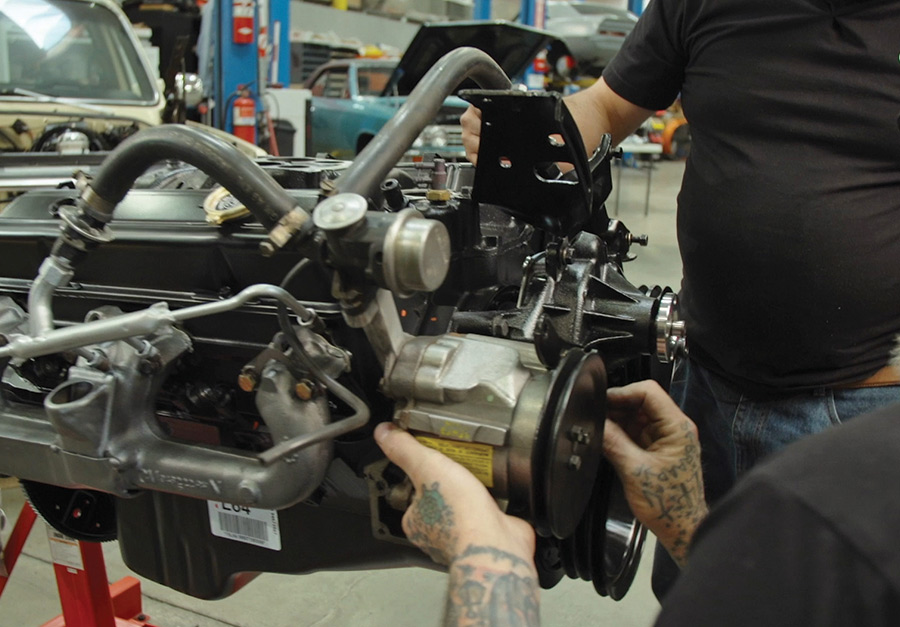

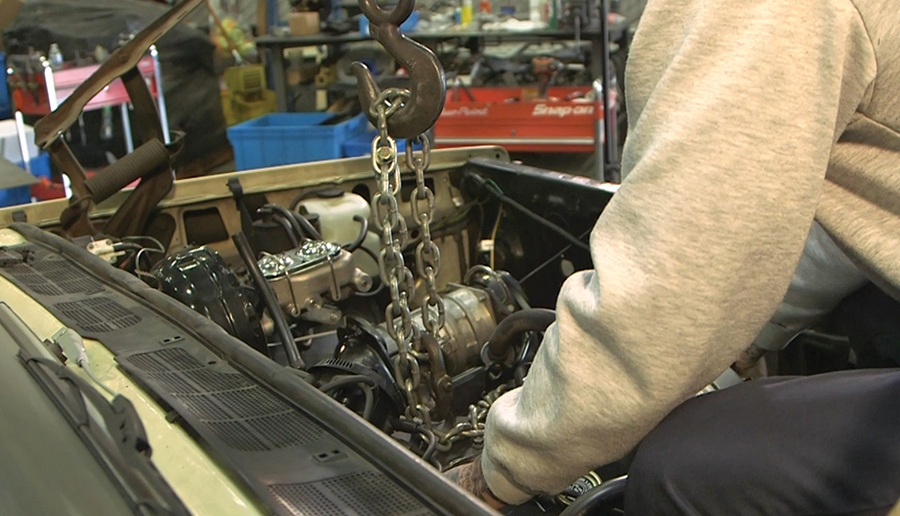

f you’ve ever owned a late-’60s and newer classic truck (Chevy or Ford and even Dodge), chances are you’ve done a crate engine install in your time. And if not, there’s always the likelihood you will sooner or later.

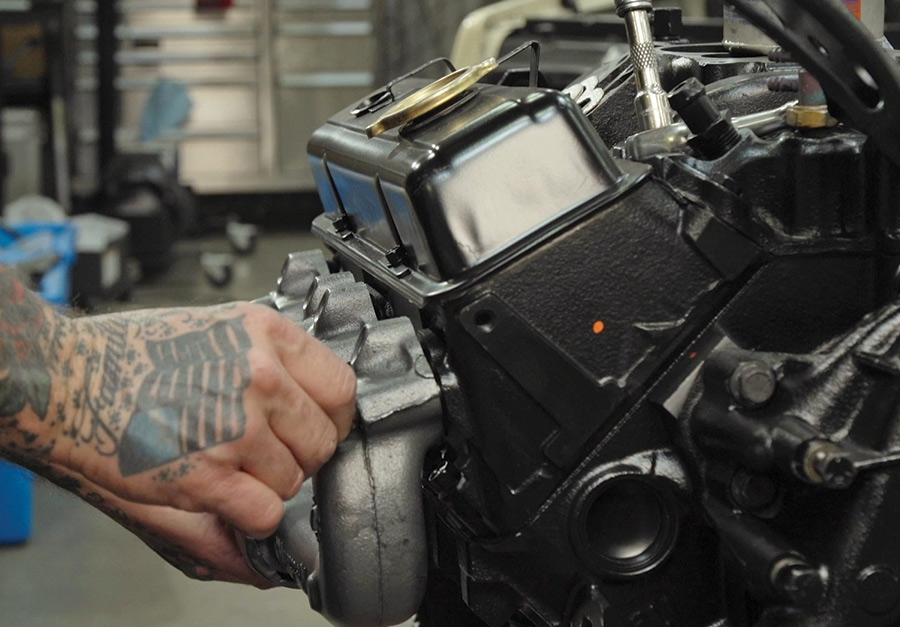

While the LS swap is still all the rage—and will continue to be for years to come—some of us are completely fine with the traditional small-block V-8 in its naturally aspirated form! So when we come upon that potential truck project with a non-running engine, the first thing to come to mind isn’t how much it’s going to cost to install even a salvaged LS engine and trans, rather, how easy it will be to get her back up and running with a new replacement crate engine! Above and beyond the direct-replacement aspect, it’s much more affordable to purchase a brand-new long-block V-8 along with all the install incidentals than it is to go the previously owned LS route.

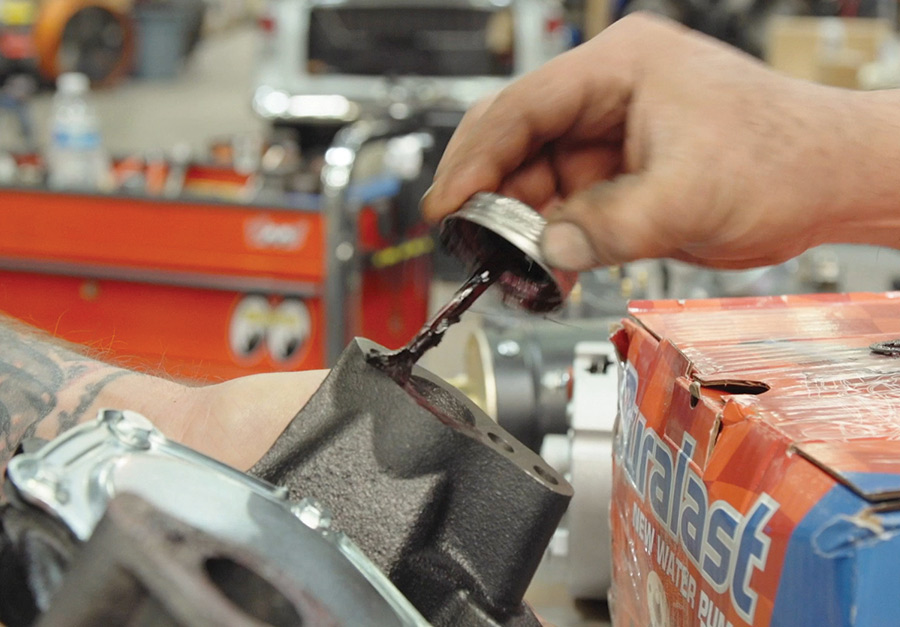

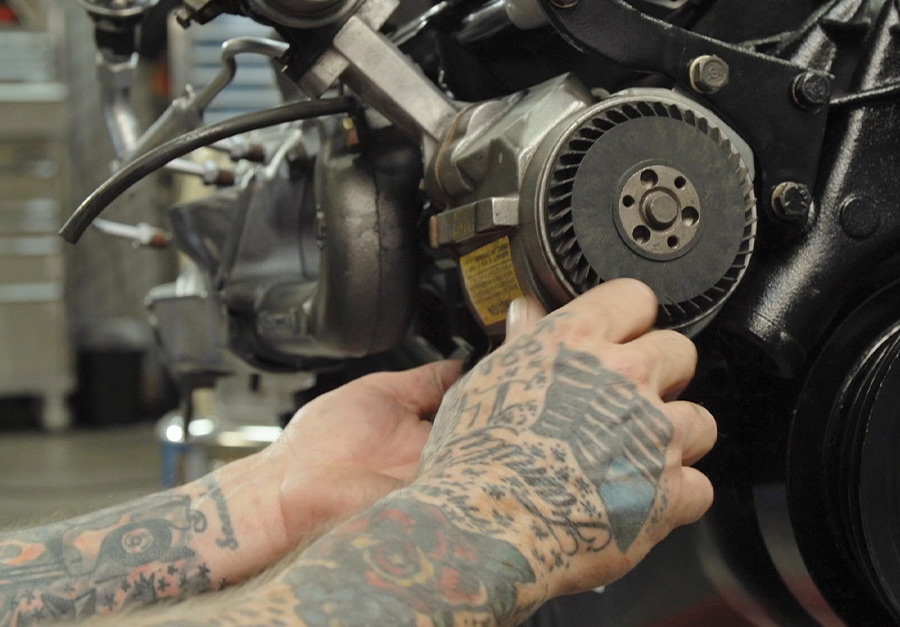

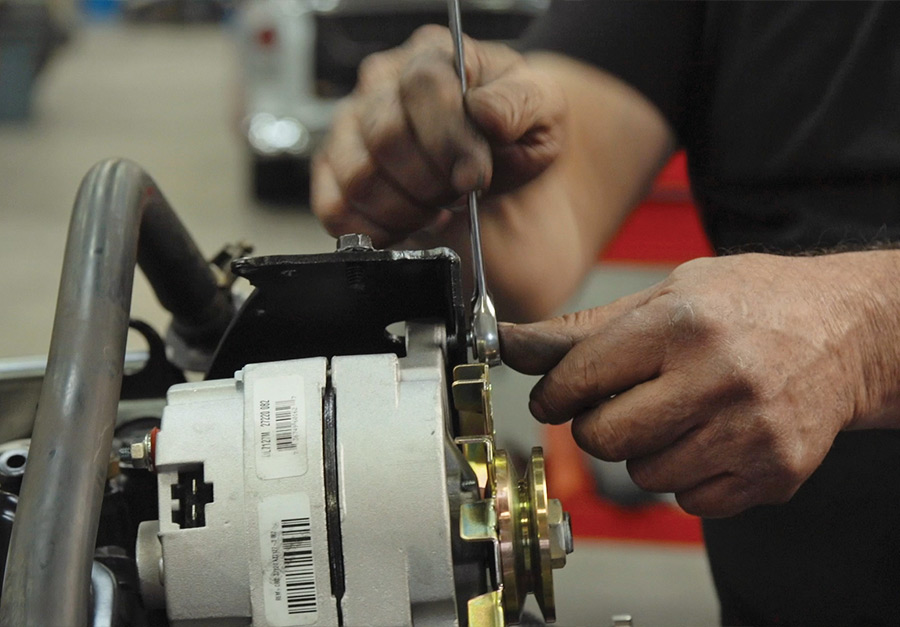

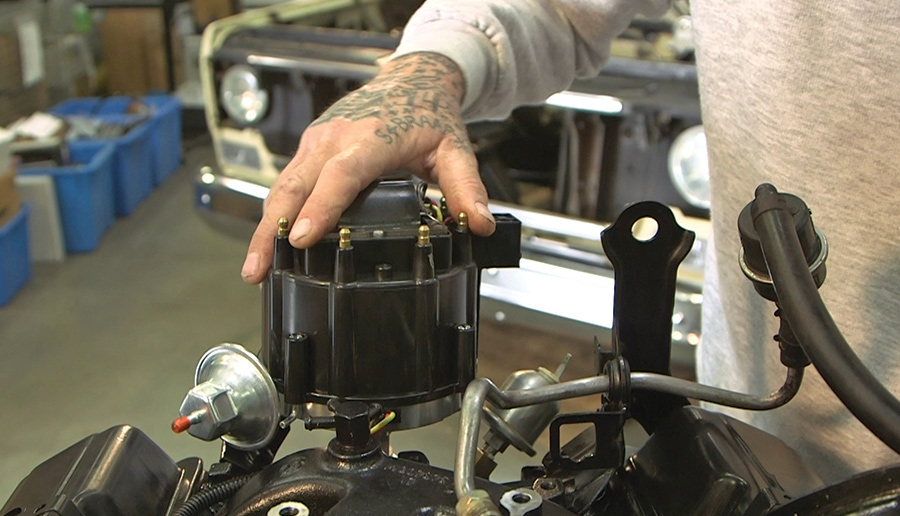

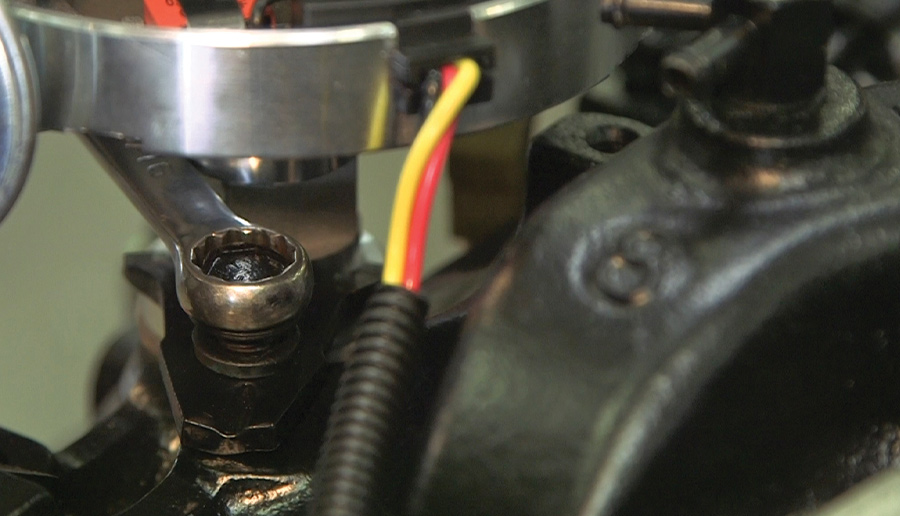

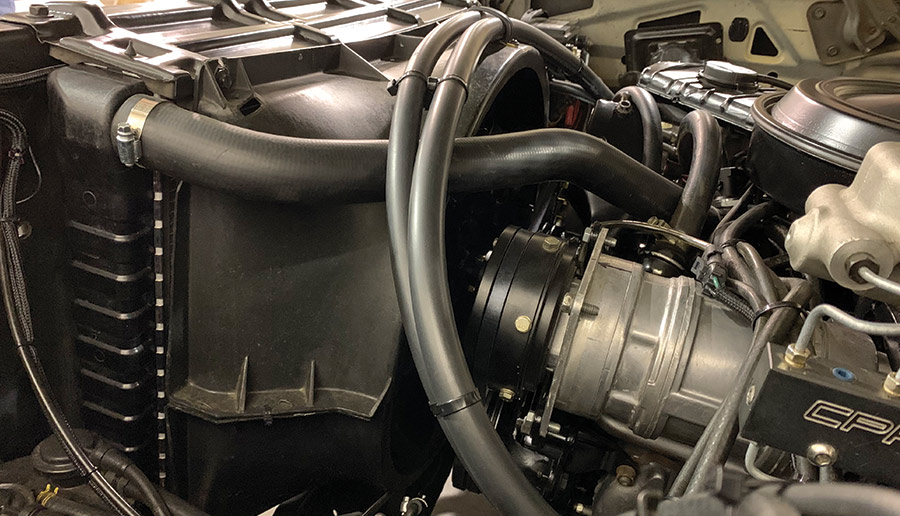

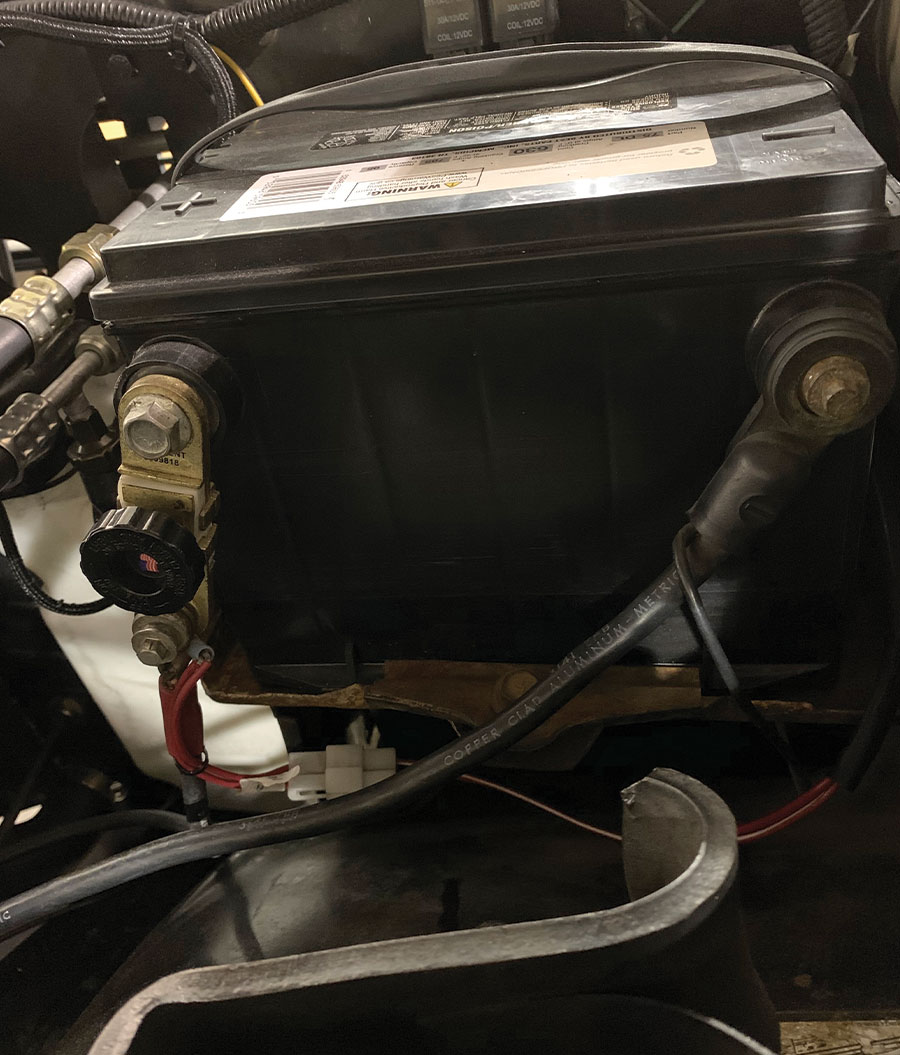

There’s even another aspect that can make any small-block engine install as simple and pain-free as possible: Duralast original-equipment quality—and better—parts. Whether it’s a water pump or engine mounts, radiator or ignition coil, every possible component you can imagine needing to help facilitate your installation is available through their expansive website (for parts availability and applications visit duralastparts.com or for parts purchasing visit autozone.com or autozonepro.com).

The great thing about using Duralast parts and accessories is, unlike your garden variety over-the-counter auto parts store brands (even with their so-called “lifetime replacement warranties”), you get the peace of mind knowing you’re installing OE-quality components that fit as they’re intended—plus Duralast parts are also backed by warranties. That in and of itself is better assurance than any implied warranty that requires your time and labor to remove, exchange, and replace said competitor’s parts!

Prior to the original small-block in this 1979 Chevy C10 finally deciding to call it quits, in anticipation we’d acquired a long-block from Gandrud Chevrolet. When that day of retirement came, however, we were ill-prepared as far as all the installation incidentals were concerned … that is, until we logged onto the our autozonepro.com account and literally found—and purchased—each and every part needed to complete the job, leaving us without the hassle of running back and forth to the parts store so we could spend the day swapping out the old for the new and getting the old girl back on the road where she belongs!

SOURCE

SOURCE

(800) 288-6966

duralastparts.com

Gandrud Performance Parts

(888) 284-7491

gmperformancemotor.com