Tech

Tech

Photography By THE AUTHOR

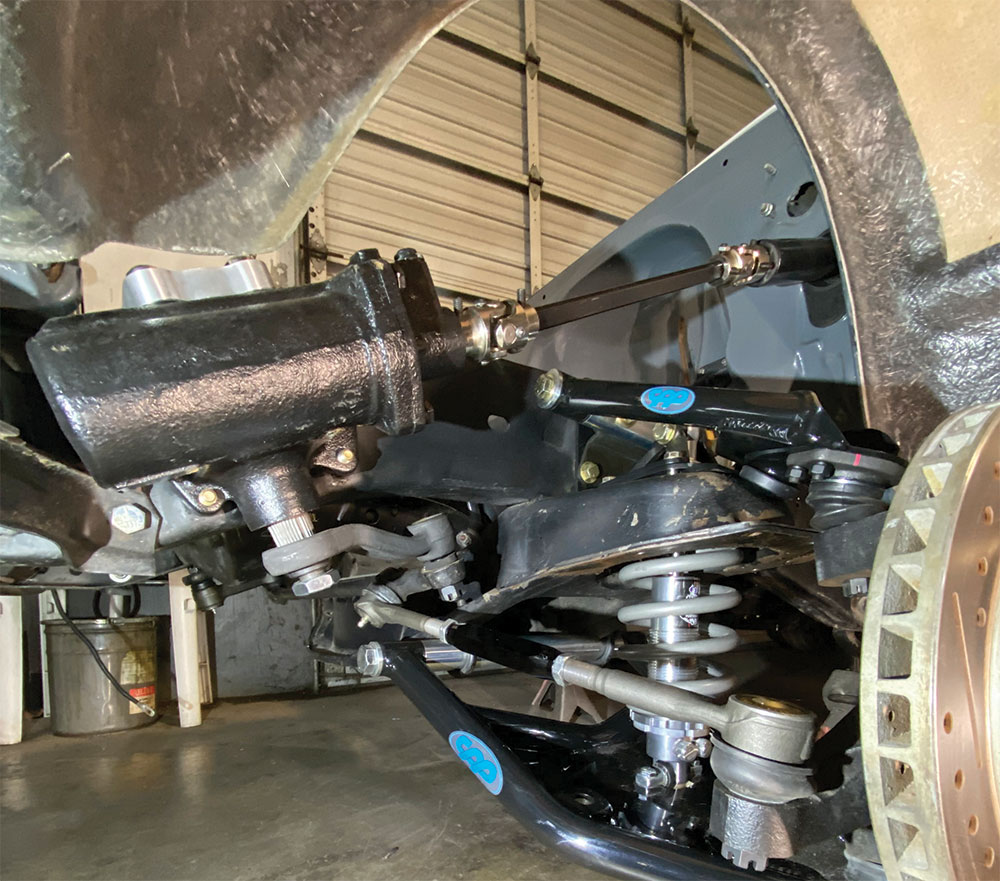

Photography By THE AUTHORast month we got our 1969 C10 project’s front suspension squared away—literally, with the correct geometry and absence of air spring adjustability—and back on all fours after months of being disabled, as it were. That just left us with properly addressing the steering components—or, in this case, the lack thereof.

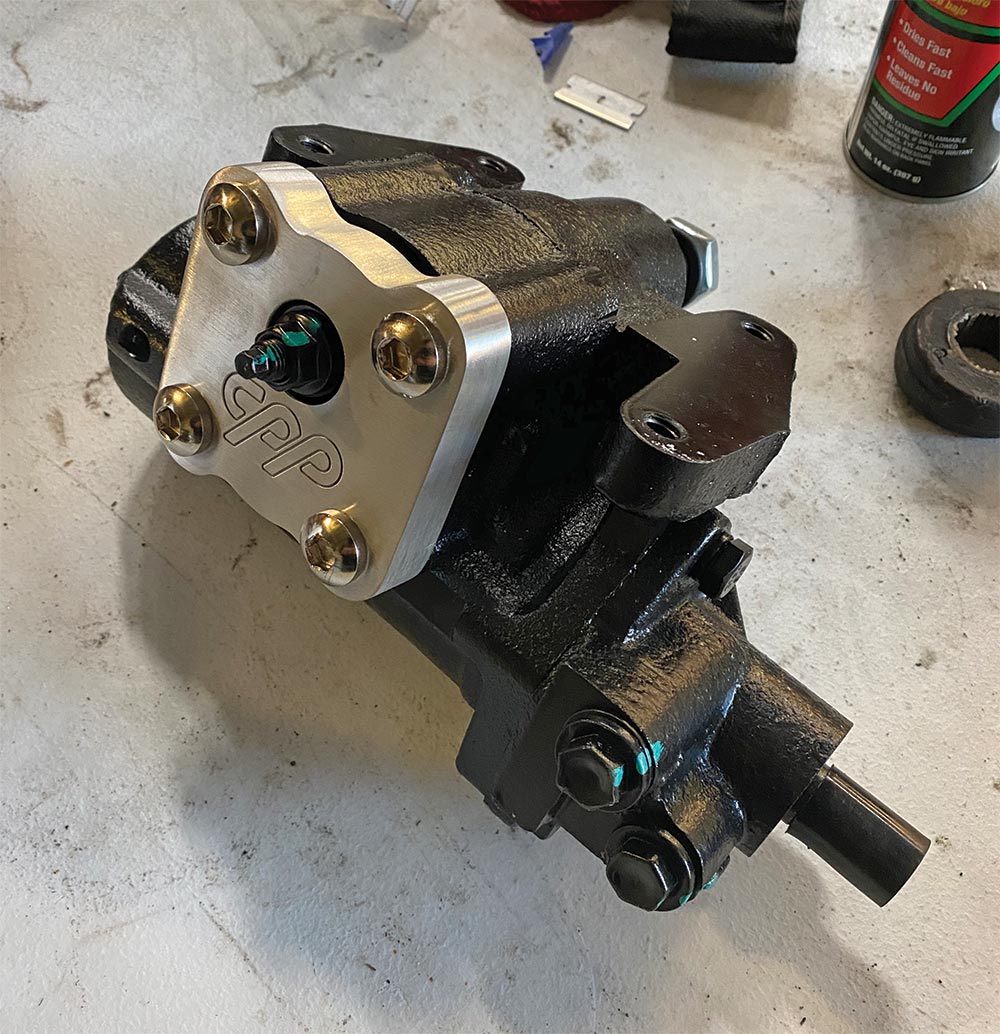

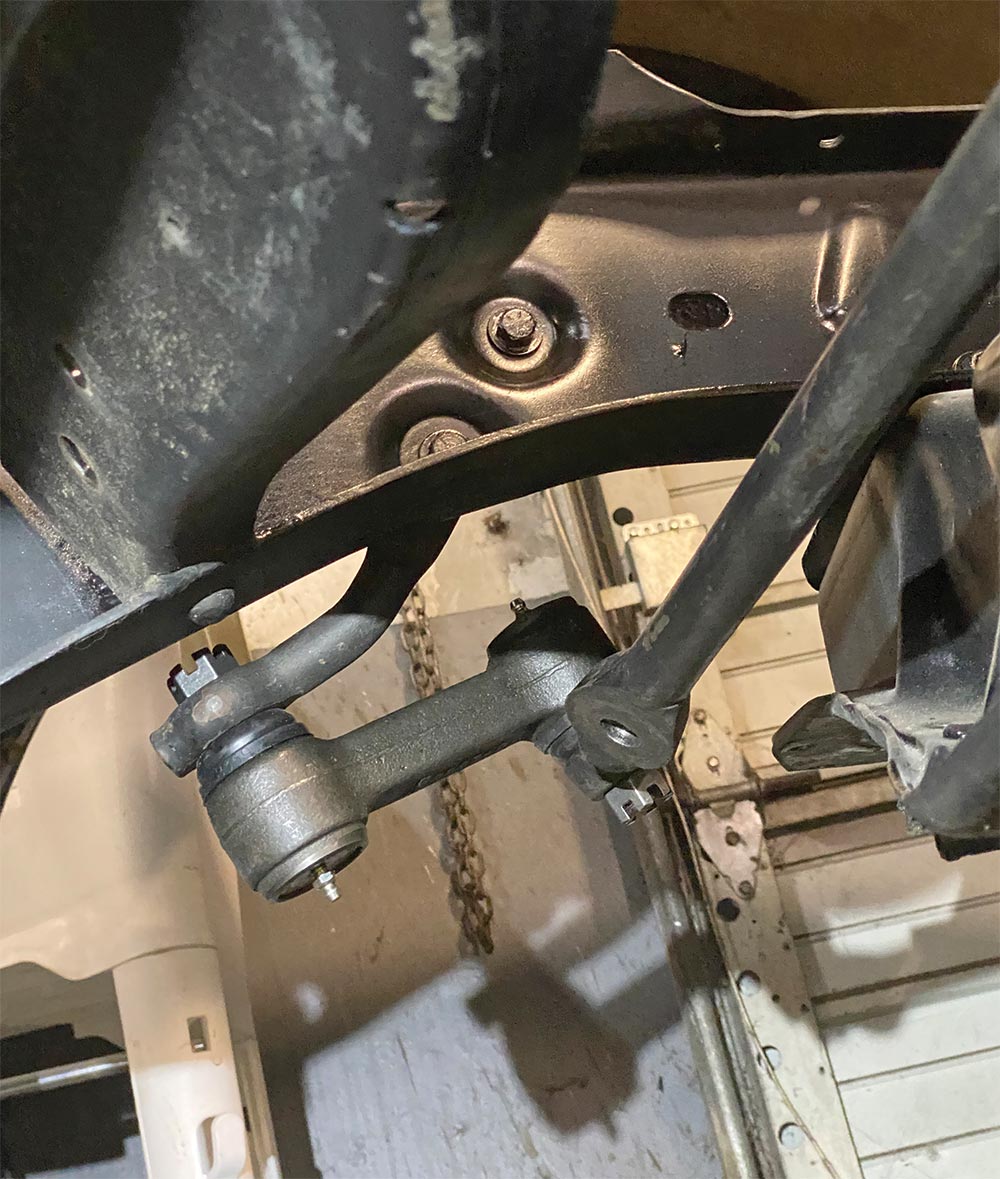

While we had the intention of replacing the worn-out, leaking power steering box from the onset of the re-transformation of our previously/poorly built truck, we hadn’t put much thought into the rest of the components controlling the soon-to-be-updated box. That is until those particular items grew legs and walked away—or, the truck’s owner left them outside and the scrap man inherited them! Either way, we had to decide what direction to go with the replacement parts: stock or upgraded aftermarket? With a number of options to choose from, our instinct told us right off the bat to go with Classic Performance Products’ (CPP) 500 Series power steering box: it’s a bolt-in replacement (or upgrade from manual), however the 500 Series boxes are brand new, not reman boxes, and feature the preferred 14:1 steering ratio as well as an improved recirculating ball gear mechanism and rotary valve for optimally responsive and smooth-as-silk performance behind the wheel. (Once the truck gets closer to completion, we’ll go back to CPP for the plumbing components to connect our new box with the Type 2 power steering pump Holley provided with their mid-mount serpentine we used on the big-block.)

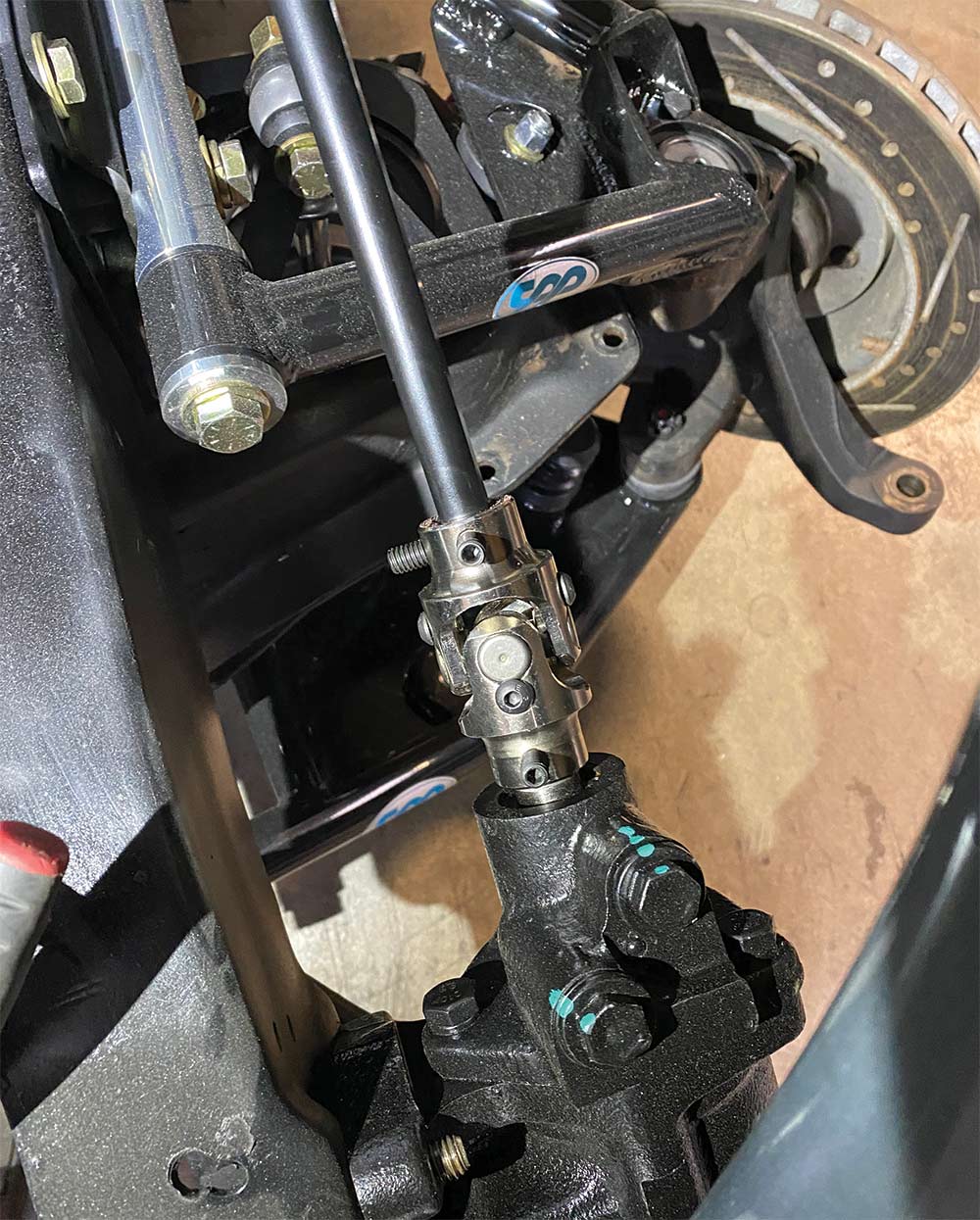

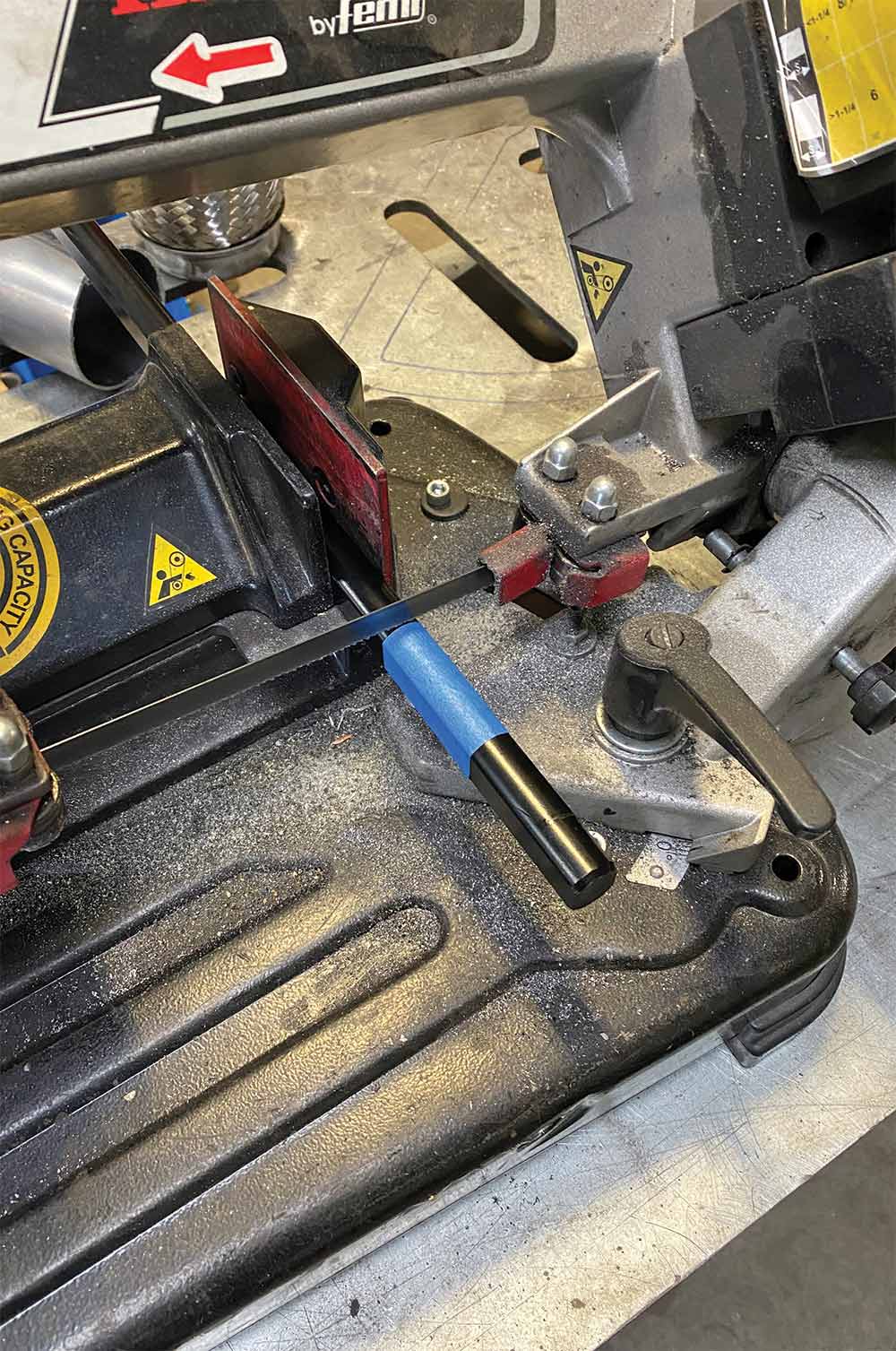

To complete our steering system, we looked into what Flaming River had to offer in the way of C10 columns and wound up ordering a powdercoated black floor shift retrofit tilt column. Just like our 500 Series box, Flaming River’s column is all “new” components, not a reman’d column. To add a bit more of a sporty look and feel, we also got our hands on—no pun intended—their no-dish (flat) Corvette-inspired three-spoke wheel—leather-wrapped, it’s only available in 15-inch diameter, which is the perfect fit for the C10. Furthermore, to fill in the gap between column and box, we obtained the necessary polished stainless 3/4DD x 3/4DD U-joint and intermediate shaft to connect with the CPP box’s 3/4-30 x 3/4DD joint. Luckily, we managed to locate the stock upper steering column mount, however, in lieu of the floor mount disappearing with the rest of the stock parts, we obtained Flaming River’s 1967-1972 C10 swivel floor mount, which is a direct bolt-in for non-modified firewalls (ours was molded in before it was painted, so we’ll have to “carefully” open the floor plate mounting holes back up!).

As the project progresses, we’re slowly moving away from the original name it was given—the Polished Turd—as literally every single piece that fits that description has been removed and subsequently replaced with a polished jewel, so to speak! And given that scenario, we’ll forgo renaming the old truck and simply get her back up and running, as best we possibly can!

SOURCEs

SOURCEs