Tech

Tech

Pickups

Photography BY THE AUTHOR

Photography BY THE AUTHORn the Aug. ’23 issue of Classic Truck Performance we began the installation of C4 Corvette front and rear suspension under Paul Wilson’s ’52 Chevy pickup with components from Don McNeil’s Flat Out Engineering. We planned on installing a small-block Chevy for power, and while there was a certain appeal to keeping our hauler all Bowtie from end to end, there was a more practical reason for Corvette suspension than brand loyalty. We knew the C4 suspension would provide excellent ride and handling characteristics and McNeil’s installation kits would make our truck’s transformation quick and easy. The one thing we didn’t anticipate was a problem with the factory frame.

McNeil has decades of experience building award-winning vehicles of all descriptions—drag racers, Bonneville competitors, show winners, and street machines. As an avid hot rodder and astute businessman, McNeil knows full well how important it is to establish the reputation for offering chassis parts that fit and work as intended, which he has done. He also knows that if you start off with a frame that is out of square the end result will be a chassis that will not work as it should. That’s why McNeil stresses that checking the frame for dimensional accuracy is the first step to installing his kits. In our case, the frame was out of square 5/16 inch, the max should be 1/8 inch. It took some effort, but with the frame square we installed the Flat Out Engineering front crossmember—which is where we left off last time.

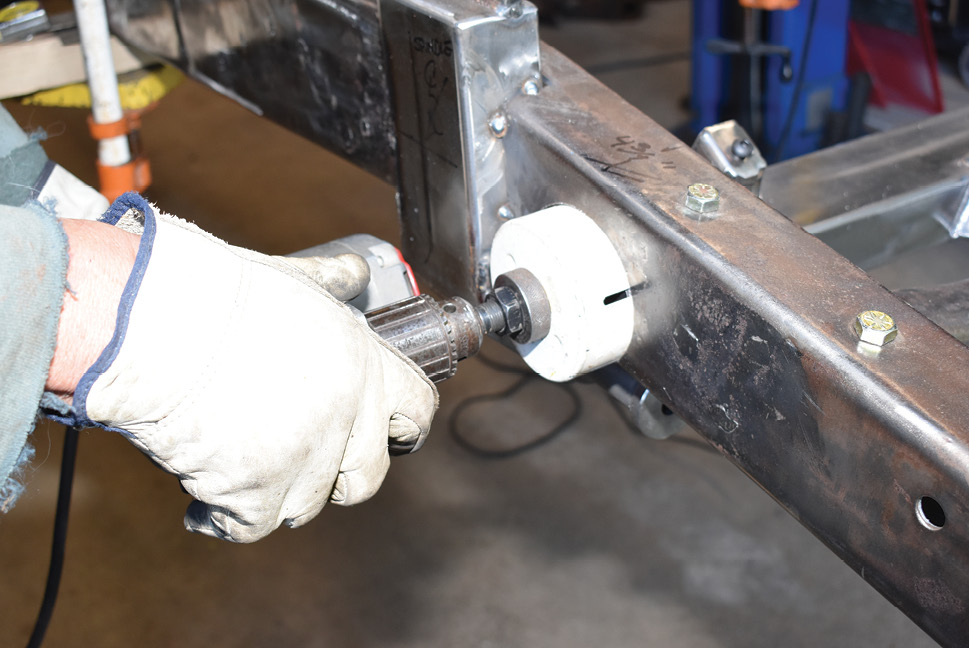

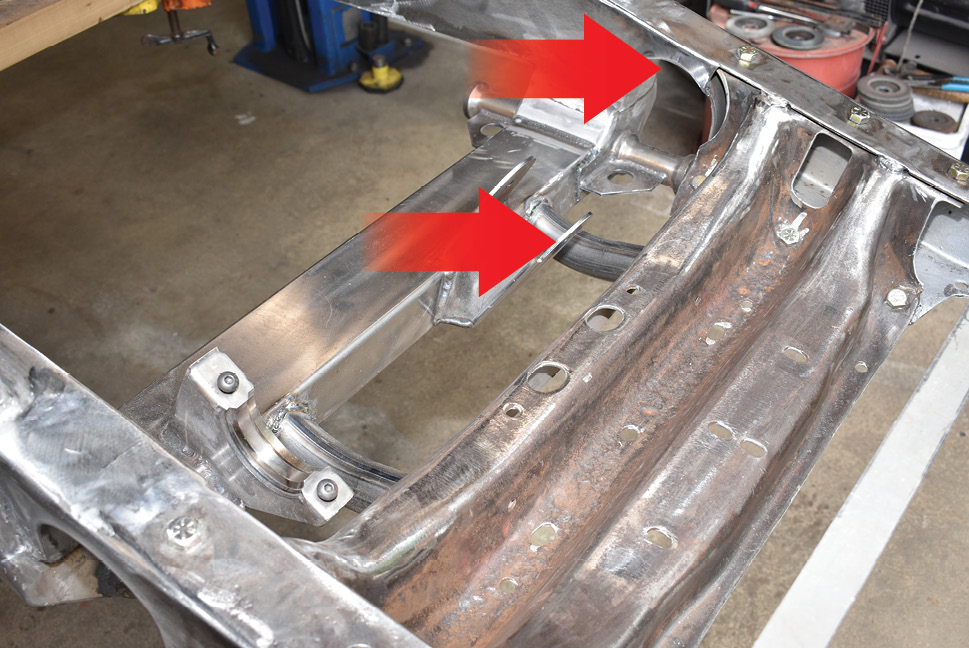

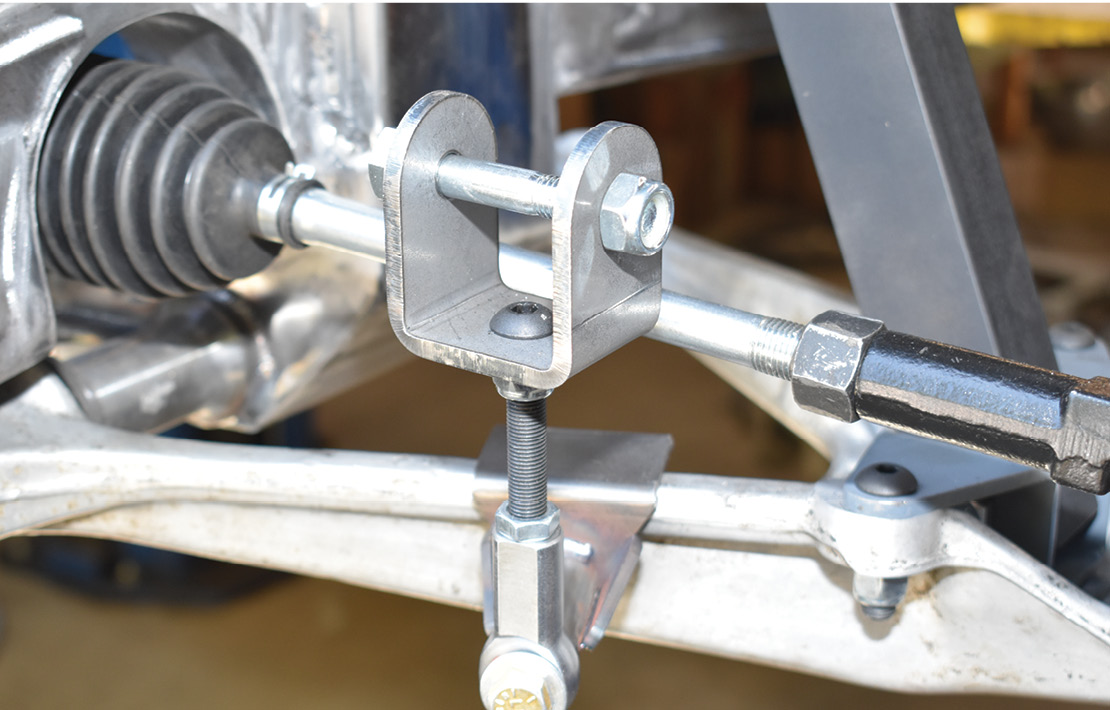

With the crossmember in place the next steps were to notch the framerails to clear the rack-and-pinion steering, install the C-notch supports, and install the Flat Out Engineering boxing plates. The trick here is to make sure the framehorns, and as a result the front crossmember that mounts the core support, remain in the proper position relative to the tops of the framerails. In this case, Wilson elected to install a pair of tubing braces from the stock front crossmember to the Flat Out Engineering crossmember. They served to maintain the stock crossmember’s position while the C-notches were cut and add some support to it as well.

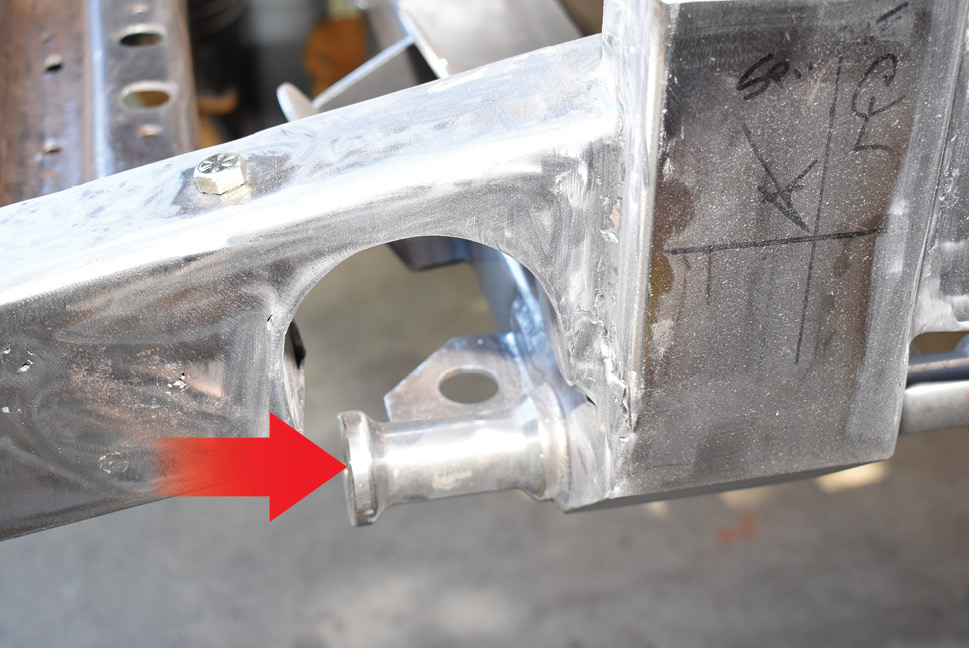

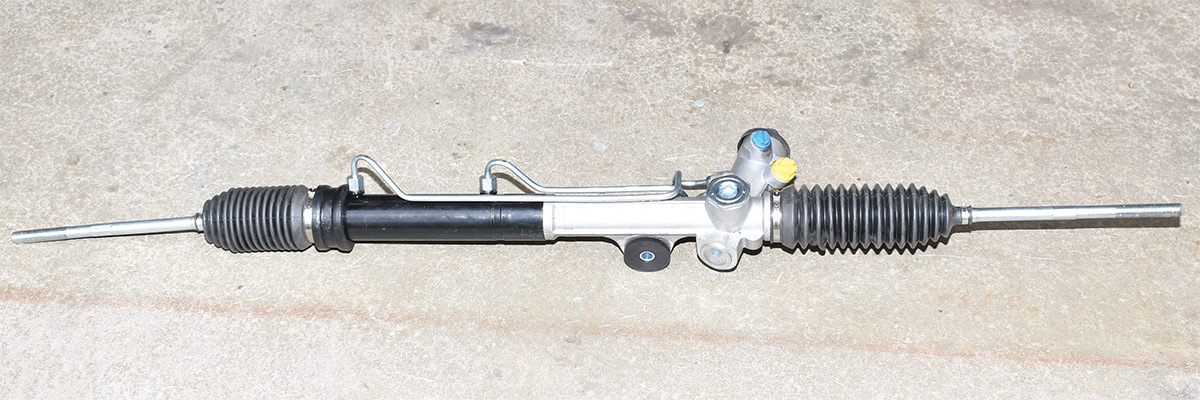

Once the front of the frame modifications were complete it was then time to turn our attention to the Corvette steering and suspension components. Wilson had come across a bargain on a complete ’86 Corvette as a parts donor, but despite the desirable components, like any car its age, time and mileage had taken their toll, so some replacement parts were needed. The power rack-and-pinion steering showed signs of leaking and one of the inner tie-rod ends was loose, so the entire assembly was replaced with a rebuild unit along with the outer tie-rod ends. Likewise, all the rubber control arm bushings were weathered and cracked so replacements from Prothane (available from Flat Out Engineering) were installed in the aluminum control arms. Finally, new ball joints were installed in the upper and lower control arms. One of the last steps to finishing the front suspension will be the installation of the sway bar, however, that will have to wait until the core support is in place to determine if the sway bar goes above or below the framerails.

Next time we’ll show how the C4 independent rear suspension is installed and how to properly assemble and adjust the Aldan coilovers.

SOURCES

SOURCES